Top 10 Small CNC Mills for Precision Machining in Your Workshop

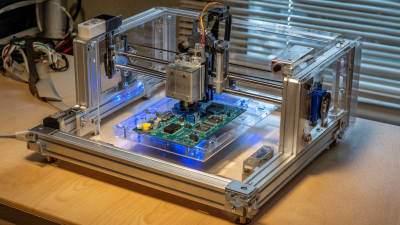

In the realm of precision machining, small CNC mills have emerged as essential tools for both hobbyists and professional machinists alike. These compact machines offer incredible versatility and accuracy, making them ideal for a diverse range of applications—from intricate prototyping to small-scale production runs. As workshops strive to maximize efficiency and precision without sacrificing valuable space, understanding the advantages of investing in a small CNC mill becomes increasingly important.

With advancements in technology, modern small CNC mills are designed to provide high performance while accommodating limited workspace. They typically offer features that enhance usability, such as user-friendly interfaces and compatibility with various materials. Whether you're looking to create custom parts, detailed engravings, or complex prototypes, the right small CNC mill can significantly improve productivity and output quality.

In this article, we will explore the top ten small CNC mills available on the market today, focusing on their specifications, capabilities, and the unique advantages they bring to your workshop. By discovering the best options suited for your specific needs, you can make an informed decision that elevates your machining projects to the next level.

Top 10 Small CNC Mills: Overview of Precision Machining Benefits

In the realm of precision machining, small CNC mills have become pivotal tools for a variety of industries, from aerospace to woodworking. These compact machines deliver exceptional accuracy, allowing craftsmen and engineers to create intricate designs with tolerances as tight as ±0.001 inches. According to a recent report by the International Federation of Robotics, the demand for CNC machinery has surged by 14% annually, reflecting the growing recognition of the efficiency and precision these tools provide.

The benefits of utilizing small CNC mills in a workshop are manifold. Notably, they significantly reduce production time while enhancing the repeatability of machining processes. A study by the National Institute of Standards and Technology highlighted that integrating CNC milling technology can lead to productivity gains of up to 50%, thus streamlining operations and minimizing waste. Additionally, these machines facilitate complex part production that would be nearly impossible to achieve with manual machining techniques, thereby expanding design possibilities for engineers and designers alike.

Furthermore, small CNC mills are designed for versatility, enabling users to switch between various materials and applications seamlessly. This adaptability is crucial in a competitive landscape where time-to-market can dictate success. According to a survey conducted by Manufacturing Insights, 68% of manufacturers reported that the adoption of CNC milling technology has allowed them to respond more quickly to market demands, underscoring the strategic advantage of investing in precision machining capabilities for any workshop.

Top 10 Small CNC Mills for Precision Machining in Your Workshop

| Model | Cutting Area (mm) | Spindle Speed (RPM) | Accuracy (mm) | Price Range (USD) |

|---|---|---|---|---|

| CNC Mill A | 500 x 400 x 400 | 24000 | 0.01 | $5,000 - $7,000 |

| CNC Mill B | 600 x 600 x 500 | 20000 | 0.02 | $4,000 - $6,000 |

| CNC Mill C | 400 x 300 x 300 | 18000 | 0.015 | $3,000 - $5,000 |

| CNC Mill D | 700 x 500 x 600 | 30000 | 0.01 | $8,000 - $10,000 |

| CNC Mill E | 500 x 400 x 400 | 22000 | 0.02 | $6,000 - $8,000 |

| CNC Mill F | 600 x 500 x 400 | 25000 | 0.015 | $7,000 - $9,000 |

| CNC Mill G | 450 x 350 x 300 | 13000 | 0.025 | $2,500 - $4,000 |

| CNC Mill H | 600 x 400 x 450 | 29000 | 0.02 | $7,500 - $9,500 |

| CNC Mill I | 400 x 300 x 400 | 17000 | 0.03 | $3,500 - $5,500 |

| CNC Mill J | 550 x 450 x 350 | 25000 | 0.015 | $4,500 - $6,500 |

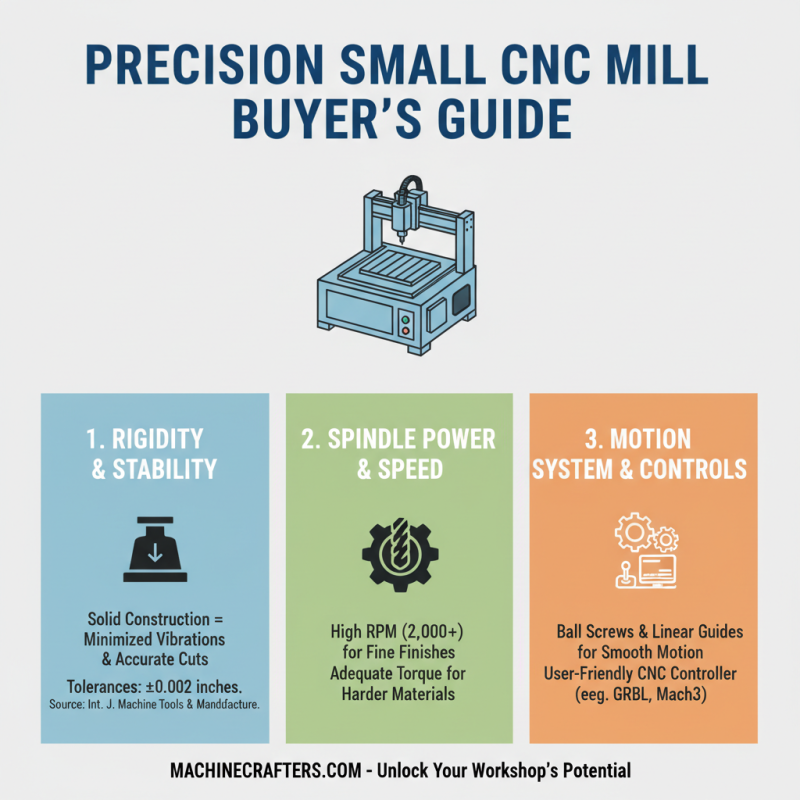

Key Features to Consider When Choosing a Small CNC Mill

When selecting a small CNC mill for precision machining in your workshop, several key features should be prioritized to ensure optimal performance and efficiency. First, consider the machine's rigidity and stability, as these factors greatly influence the quality of the finished product. A solid base and robust construction minimize vibrations, facilitating more accurate cuts. According to a report from the International Journal of Machine Tools and Manufacture, machines with higher rigidity often produce tolerances as tight as ±0.002 inches, making them ideal for intricate designs.

Another critical aspect is the milling speed and feed rates. CNC mills equipped with high-speed spindles can considerably enhance productivity, particularly when working with hard materials. Data from industry analyses indicate that mills capable of achieving spindle speeds above 10,000 RPM tend to outperform those with lower specifications, delivering superior surface finishes and reducing production time.

**Tips:** Always opt for a machine that provides advanced software options, as this will enhance your ability to create complex designs effortlessly. Additionally, consider the availability of support and training, which can be crucial for maximizing your milling capabilities in a competitive market. Investing in a model with user-friendly controls can significantly reduce the learning curve for new operators, contributing to a more efficient workflow.

Comparison of Leading Small CNC Mills Based on Accuracy and Performance

When selecting a small CNC mill for precision machining,

accuracy and performance are paramount. Recent industry reports indicate that machines capable of maintaining

tolerances within ±0.001 inches (0.025 mm) stand out in the market.

Such precision is crucial for applications ranging from intricate prototyping to the creation of automotive components.

Advanced models utilize high-quality ball screws and linear guides, which contribute to enhanced rigidity and reduced backlash,

enabling higher precision in machining operations.

Performance metrics such as spindle speed and feed rates further differentiate these small CNC mills. Many models boast

spindle speeds reaching up to 24,000 RPM, allowing for faster material removal

and improved surface finish quality. According to a survey conducted by a reputable manufacturing analyst firm,

small CNC mills with a combination of high RPM and optimum feed rates are reported to increase overall machining efficiency

by up to 30%. This efficiency is not only an advantage in terms of time savings

but also reduces wear on the equipment, leading to lower maintenance costs over time. As workshops increasingly demand both

performance and precision, selecting a small CNC mill that excels in these areas is essential for achieving optimal results.

Cost Analysis: Investment and ROI of Small CNC Milling Machines

When considering the investment in small CNC milling machines, understanding the cost analysis and potential return on investment (ROI) is crucial for any workshop. The initial cost of acquiring a small CNC mill can vary significantly based on features, capabilities, and specifications. While the upfront cost may seem substantial, it is essential to view this as a long-term investment. These machines can dramatically increase productivity and precision, leading to cost savings in production time and material waste over time.

Tips for making a sound investment include evaluating the specific needs of your workshop and projecting future machining demands. Prioritize machines that offer versatility and adaptability to different materials and projects. Additionally, consider the total cost of ownership, which includes maintenance and potential upgrade costs, when calculating expected ROI.

Another critical aspect is analyzing the machine's operational efficiency. A CNC mill that can operate continuously with minimal downtime ensures that you maximize its output. Investing in training for your staff can also enhance machine utilization, allowing you to achieve optimal results from your small CNC milling equipment. This strategic approach to cost analysis will enable informed decisions that benefit both your current operations and future growth.

Future Trends in CNC Milling Technology for Precision Machining

As we look to the future of CNC milling technology, several trends are emerging that promise to enhance precision machining capabilities in workshops. One of the most significant advancements is the integration of artificial intelligence and machine learning into CNC systems. These technologies facilitate smarter machining processes by predicting tool wear, optimizing cutting paths, and adapting operations in real time. Such capabilities not only improve productivity but also ensure that the final products meet tighter tolerances, which is increasingly demanded in industries such as aerospace and medical device manufacturing.

Another notable trend is the growth of additive manufacturing techniques alongside traditional CNC milling. Hybrid machines that can both mill and 3D print allow for the creation of complex geometries that were previously unattainable. This synergy between subtractive and additive processes leads to more efficient production methods, enabling manufacturers to produce lightweight, intricate parts with reduced material waste. As these technologies evolve, precision machining will not only become more efficient but will also open new avenues for innovation, allowing workshops to tackle ever more challenging projects with confidence.

Top 10 Small CNC Mills for Precision Machining

Related Posts

-

Discover Superior Manufacturing with the Best Desktop CNC Mill from Top Chinese Factories

-

Finding Reliable Manufacturers for the Best Small CNC Mill Solutions

-

Unlocking Precision: The Key Advantages of CNC Milling Machines for Modern Manufacturing

-

Shaping the Future of CNC Machines at the 138th Canton Fair in 2025

-

Unlocking Precision: How CNC Machines Revolutionize Manufacturing with 30% Efficiency Gains

-

Unlocking Creativity with Compact CNC Machines for Innovative Projects

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska