Top Home CNC Machines of 2025: What You Need to Know Before Buying

As we look toward the future of manufacturing and DIY projects, the importance of home CNC machines continues to grow. In 2025, these sophisticated tools are not just luxuries for hobbyists; they are becoming essential equipment for many home workshops. Renowned CNC expert Dr. Emily Hartley emphasizes this point by stating, "In the world of fabrication, a home CNC machine opens up endless possibilities for creativity and precision that were once reserved for industrial settings." With this shift in accessibility, it’s crucial for consumers to educate themselves on the various options available in the market.

Choosing the right home CNC machine can feel overwhelming, given the vast array of features, sizes, and price points. Whether you're a seasoned woodworker or a novice looking to bring your design ideas to life, understanding the key aspects of these machines is vital. From the intricacies of software compatibility to the types of materials you can work with, knowing what to look for can enhance your crafting experience and outcomes significantly. As we dive into the top home CNC machines of 2025, we will explore essential factors and expert recommendations that can guide you in making an informed decision tailored to your creative needs.

Overview of Home CNC Machines: Types and Functions

Home CNC machines have gained significant popularity due to their versatility and accessibility for hobbyists and small business owners. There are several types of CNC machines available, each designed for specific functions. The most common types include CNC routers, CNC mills, and CNC plasma cutters.

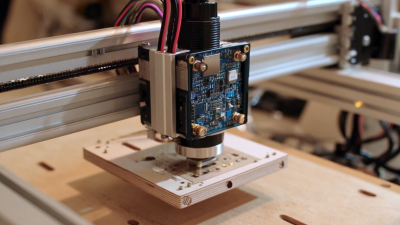

CNC routers are primarily used for woodworking and can handle a variety of materials, such as plastic and composites. They excel in creating detailed carvings and intricate designs.

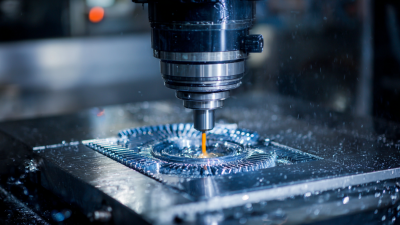

On the other hand, CNC mills offer more precision and are suitable for working with metal and other rigid materials. These machines are ideal for fabricating parts and prototypes, making them essential in engineering and manufacturing sectors.

CNC plasma cutters, however, are specialized for cutting metal sheets with high-temperature plasma, making them perfect for artistic creations and industrial applications. Understanding the differences in types and functions is crucial when selecting the right home CNC machine tailored to your specific projects and material needs.

Key Features to Consider When Buying a Home CNC Machine

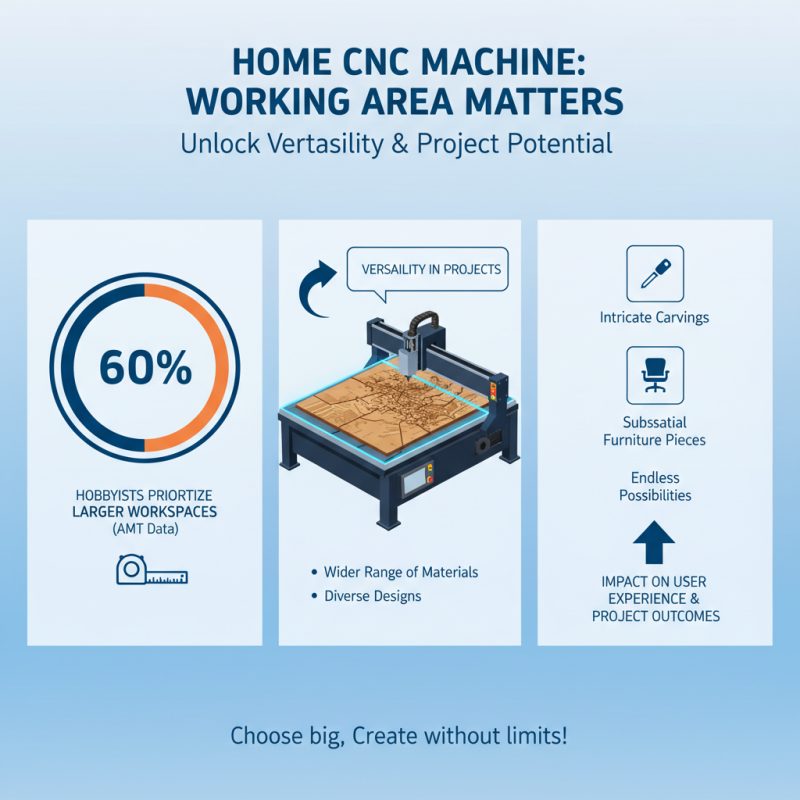

When considering a home CNC machine, several key features can significantly impact your user experience and project outcomes. One of the primary factors is the machine's working area. Data from the Association for Manufacturing Technology indicates that 60% of hobbyists prioritize larger workspaces for versatility in projects. A spacious working envelope allows users to tackle a wider range of materials and designs, from intricate carvings to substantial furniture pieces.

Another crucial aspect is the precision and resolution of the CNC machine. Features such as stepper motor quality and control systems are essential for achieving high accuracy. According to a report by MarketsandMarkets, machines with a resolution of 0.01 mm or better are increasingly sought after, as they enable users to create complex and detailed components. Additionally, ease of use is vital; machines that come with intuitive software and user-friendly interfaces can attract novices, as more than 70% of new users find a steep learning curve a major deterrent when entering the world of CNC machining.

Top Brands and Models of CNC Machines for Home Use in 2025

When considering CNC machines for home use in 2025, it's essential to focus on the top brands and models that cater to various needs and skill levels. Brands like X-Carve and Shapeoko remain popular among hobbyists for their reliability and versatility. The X-Carve, known for its modular design, allows users to customize their setups, making it ideal for both beginners and advanced users. On the other hand, the Shapeoko series offers robust construction and impressive capabilities for woodwork and metal projects alike, appealing to those who prioritize durability and performance.

Another brand worth noting is the Snapmaker, which has gained attention for its all-in-one capabilities. This machine combines 3D printing, laser engraving, and CNC carving into a single device, making it a great choice for makers who want to explore multiple fabrication techniques without investing in separate machines. When selecting a CNC machine, consider your primary projects, the materials you'll be working with, and the available workspace. The right model can significantly enhance your creative process and yield impressive results in home projects.

Top Home CNC Machines of 2025: Market Analysis

This bar chart illustrates the estimated market share of various types of CNC machines for home use in 2025. As represented, Milling Machines and Routers are predicted to dominate the market, showing significant demand among hobbyists and small businesses.

Cost Breakdown: Budgeting for Your Home CNC Machine Purchase

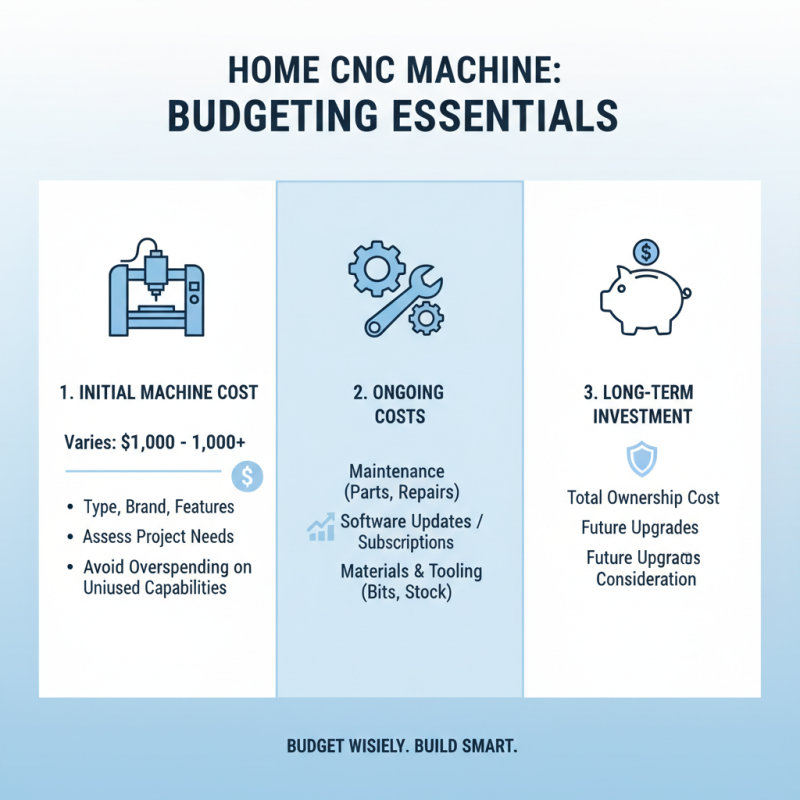

When considering the purchase of a home CNC machine, budgeting is one of the most crucial steps. The initial cost of the machine itself can vary significantly based on the type, brand, and features. Entry-level models may start around $1,000, while high-end machines can run into several thousands of dollars. It's vital to assess what features are necessary for your projects to avoid overspending on capabilities you might never use. Additionally, factor in ongoing costs such as maintenance and software updates, which can add to your long-term investment.

Apart from the machine price, potential buyers should also consider additional expenses like tooling, materials, and workspace setup. Quality cutting tools can enhance performance but may require a significant upfront investment. Furthermore, ensuring a dedicated workspace with proper ventilation, power supply, and safety equipment will help optimize your CNC operations. By taking the time to calculate these costs in advance, you can create a realistic budget that aligns with your crafting goals and avoids any financial surprises.

Maintenance and Support Tips for Home CNC Machines

When investing in home CNC machines, maintenance and support should be a top priority. Regular upkeep ensures that your machine performs optimally and extends its lifespan. Simple tasks like cleaning and lubricating moving parts can prevent wear and tear, while checking software updates can enhance functionality and precision. Engaging with user manuals and online resources can also provide invaluable tips for troubleshooting and routine maintenance tasks.

Moreover, the support network is crucial for any CNC machine owner. Many manufacturers offer dedicated customer support and online forums where users can share experiences and solutions. As the CNC landscape evolves with advancements, it’s beneficial to stay informed about new tools and technologies that can help improve your projects. Establishing a routine for both maintenance and seeking help when needed will ultimately lead to a more productive and satisfying CNC experience at home.

Top Home CNC Machines of 2025: What You Need to Know Before Buying - Maintenance and Support Tips for Home CNC Machines

| Machine Type | Max Cutting Area (mm) | Spindle Power (W) | Accuracy (mm) | Maintenance Frequency | Support Availability |

|---|---|---|---|---|---|

| CNC Router | 600 x 900 | 1500 | 0.02 | Monthly | 24/7 Online |

| CNC Mill | 500 x 500 | 2000 | 0.005 | Quarterly | Business Hours |

| CNC Plasma Cutter | 1200 x 2400 | 1000 | 0.1 | Biannual | Weekend Support |

| Desktop CNC Machine | 300 x 300 | 500 | 0.01 | Monthly | Online Ticketing |

Related Posts

-

Exploring Unique Features and Applications of Best CNC Manufacturing Solutions

-

Unmatched Excellence in Best CNC Metal from Leading Chinese Manufacturers

-

The Future of Advanced CNC Machine Technologies in Global Manufacturing

-

Digital Revolution in Manufacturing Discover the Best Router CNC for Your Needs

-

Discovering the Advantages of the Best Smart CNC Technology for Modern Manufacturing

-

7 Innovative Best CNC Milling Techniques You Should Know About Today

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska