2025 Top 5 Small CNC Machines for Metal: Discover the Best Precision Tools for Metalworking

As the demand for precision engineering continues to rise, the significance of efficient and compact machinery becomes increasingly apparent. Among these, the small CNC machine for metal stands out as a vital tool for both hobbyists and professionals alike. In 2025, the market is expected to showcase an impressive array of small CNC machines designed to meet the diverse needs of metalworkers. These machines not only provide exceptional accuracy but also enhance workspace efficiency, allowing metalworking enthusiasts to produce intricate designs without the need for large-scale machinery.

In this comprehensive guide, we will explore the top five small CNC machines for metal, highlighting their standout features, versatility, and overall value for users. Whether you are a seasoned machinist or just starting on your metalworking journey, understanding the best options available will empower you to make informed decisions tailored to your specific requirements. Join us as we delve into the world of precision tools, where each small CNC machine for metal is designed to maximize productivity while ensuring the utmost quality in your projects.

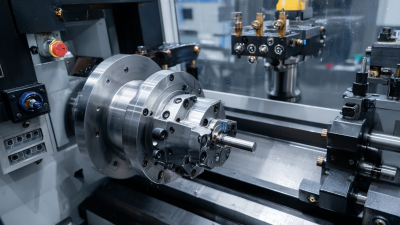

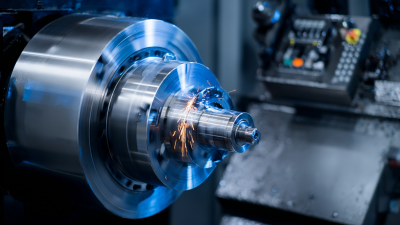

Overview of CNC Machines for Metalworking: Key Features and Benefits

CNC machines have revolutionized metalworking by providing unparalleled precision and efficiency. These advanced tools utilize computer numerical control to automate the machining process, allowing for complex shapes and tight tolerances that manual machining simply cannot achieve. Key features of small CNC machines for metalworking include robust construction, high spindle speeds, and a variety of compatible cutting tools. These specifications not only enhance performance but also extend the lifespan of the machine, making it a wise investment for any metal shop.

CNC machines have revolutionized metalworking by providing unparalleled precision and efficiency. These advanced tools utilize computer numerical control to automate the machining process, allowing for complex shapes and tight tolerances that manual machining simply cannot achieve. Key features of small CNC machines for metalworking include robust construction, high spindle speeds, and a variety of compatible cutting tools. These specifications not only enhance performance but also extend the lifespan of the machine, making it a wise investment for any metal shop.

The benefits of using small CNC machines for metalworking are manifold. Their compact size allows them to fit into smaller workshops while still delivering powerful output. Additionally, they are often user-friendly, equipped with intuitive software that makes programming and operation accessible even for beginners. With consistent results and a significant reduction in production time, these machines empower metalworkers to increase output and improve the quality of their products, catering to both small-scale projects and larger demands in the industry.

Choosing the Right Size and Weight for Your Small CNC Machine

When selecting a small CNC machine for metalworking, size and weight are critical factors that significantly influence both performance and usability. According to an industry report by MarketsandMarkets, the global CNC machine market is projected to grow from $77.97 billion in 2020 to $105.85 billion by 2025, highlighting the increasing demand for compact and efficient machining tools. Smaller machines, typically weighing under 200 kg, are preferable for home workshops or small businesses due to their maneuverability and lower space requirements.

However, it's essential to balance size with capability. A machine that's too small may lack the power to handle tougher materials or larger projects, leading to inefficiencies. The same report indicates that about 35% of metalworking shops are investing in machines that enhance precision without significantly increasing size. This trend emphasizes the importance of selecting a CNC machine that not only fits your workspace but also meets your machining needs, reflecting a growing preference for versatile tools that optimize both productivity and precision. As you explore options, consider how the dimensions of the machine impact its operational efficiency and the types of materials you intend to work with.

2025 Top 5 Small CNC Machines for Metal

Explore the leading small CNC machines for metalworking, focusing on size and weight to ensure precision and portability in your projects.

Top CNC Machine Brands: Reputation, Support, and Reliability

When selecting the CNC machines for metalworking in 2025, it's crucial to consider brand reputation, support, and reliability. According to a recent industry report by Statista, approximately 70% of metalworking professionals prioritize vendor support when choosing machinery. This underscores the importance of selecting brands that not only deliver high-quality products but also have strong customer service and support networks.

Leading brands like Haas Automation, DMG Mori, and Mazak have consistently ranked high in customer satisfaction due to their robust support systems and reliable machines. A survey conducted by a manufacturing trade association revealed that 87% of users of these brands reported minimal downtime, attributing it to superior engineering and readily available technical assistance. Furthermore, data from the Precision Metalforming Association indicates that investing in reputable CNC brands can result in a 20% increase in productivity, making it essential for businesses to prioritize both the machinery's precision capabilities and the reliability of the manufacturer.

Essential Accessories to Enhance Your Small CNC Machining Experience

When looking to enhance your small CNC machining experience, incorporating the right accessories is essential. According to a recent report by Research and Markets, the CNC machine tool market is projected to reach $100 billion by 2025, indicating a growing interest in precision tools across various industries. Investing in essential accessories, such as precision vises, collets, and tool holders, can significantly improve the efficiency and accuracy of your machining projects. A well-equipped workstation not only boosts productivity but also ensures higher-quality finishes in metalworking.

Tip: Always choose accessories that are compatible with your CNC machine specifications to avoid issues related to fit and function. For example, high-quality collets can drastically reduce the runout in your tooling, leading to improved precision. Additionally, consider using coolant systems designed for small CNC machines to help manage tool temperatures and enhance tool life.

Moreover, additional tools like digital calipers and height gauges can be invaluable for ensuring accurate measurements and setups. A survey reflected in the "CNC Machining Market Analysis" report highlighted that 60% of manufacturing firms increased their output efficiency by integrating advanced measurement tools alongside their CNC equipment. In this competitive landscape, having the best precision tools and accessories can make all the difference in achieving outstanding results in metalworking.

Comparative Analysis of the Top 5 Small CNC Machines: Specs and Pricing

When it comes to choosing the ideal small CNC machines for metalworking, a comparative analysis of the top five options reveals significant differences in specifications and pricing. Each machine is crafted to cater to various needs, offering unique features that impact performance, ease of use, and affordability. For example, some models may boast higher spindle speeds, enabling quicker machining processes, while others prioritize precise cutting capabilities with advanced tooling options.

In terms of pricing, a careful examination highlights how budget constraints influence the selection process. While premium machines might offer cutting-edge technology and reliability, they can also come with a hefty price tag. Conversely, more economical options may lack certain advanced features but still provide excellent precision for small-scale projects. Additionally, understanding the long-term operational costs, such as maintenance and material compatibility, is crucial for making an informed decision. This comparison not only helps in identifying the best machines for specific metalworking tasks but also aids in aligning choice with budgetary considerations.

2025 Top 5 Small CNC Machines for Metal

| Model | Cutting Area (X x Y x Z) mm | Spindle Power (kW) | Max Speed (RPM) | Price (USD) |

|---|---|---|---|---|

| Model A | 300 x 200 x 150 | 1.5 | 24000 | $4,500 |

| Model B | 400 x 300 x 200 | 2.2 | 22000 | $6,200 |

| Model C | 350 x 250 x 175 | 2.0 | 20000 | $5,000 |

| Model D | 500 x 400 x 250 | 3.0 | 18000 | $8,000 |

| Model E | 450 x 350 x 200 | 2.5 | 21000 | $7,500 |

Related Posts

-

Excellence in Manufacturing from China Bringing the Best Mini CNC Machines to the World

-

Unlocking Global Markets: The Role of Import-Export Certifications for the Best Small CNC Machines in Metal Fabrication

-

Innovative Insights into Mini CNC Machine Technology Trends Shaping 2025 Global Manufacturing

-

Unlocking the Power of CNC Turning Tips for Global Buyers in the Digital Era

-

Mastering Precision with Small CNC Lathes for Your Next Project

-

Essential Checklist for Choosing the Right Wood CNC Machine for Your Business Needs

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska