Maximizing Efficiency: The Unmatched Advantages of CNC Wood Cutting Machines for Modern Manufacturing

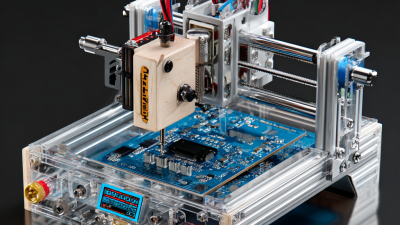

In the fast-evolving landscape of modern manufacturing, efficiency is paramount, particularly in the woodworking industry. The ascent of the CNC wood cutting machine has revolutionized production processes, offering unmatched precision and speed. According to a report by the International Woodworking Machinery Association, the adoption of CNC technology in wood processing can enhance productivity by up to 50%, significantly reducing waste and labor costs. Furthermore, a study by Grand View Research highlights that the global CNC machine market is expected to reach $100 billion by 2025, reflecting the growing reliance on these advanced tools. As manufacturers strive to meet the demands of an increasingly competitive market, the CNC wood cutting machine stands out as a critical investment for optimizing operations and achieving superior output.

The Evolution of CNC Technology: Transforming Wood Cutting Processes

The evolution of CNC technology has ushered in a transformative era for wood cutting processes in modern manufacturing. With precise automation capabilities, CNC wood cutting machines enable manufacturers to achieve unprecedented levels of accuracy and efficiency. According to industry reports, CNC machines can reduce production time by up to 50% compared to traditional woodworking methods, allowing companies to meet increasing market demands swiftly.

Advancements in CNC technology have also significantly enhanced the quality of wood products. High-performance machines are now equipped with sophisticated software that facilitates intricate designs and complex cuts that were previously unmanageable. Recent studies suggest that the implementation of CNC technology in wood manufacturing results in a 20% improvement in material yield, effectively minimizing waste and reducing costs. This not only benefits manufacturers economically but also supports sustainability efforts in the woodworking industry by promoting responsible resource usage. As CNC technology continues to evolve, its advantages will only expand, solidifying its essential role in modern manufacturing practices.

Key Benefits of CNC Wood Cutting Machines in Modern Manufacturing

CNC wood cutting machines are revolutionizing modern manufacturing processes, offering unparalleled precision and efficiency. These advanced machines utilize computer numerical control to execute complex cutting tasks with remarkable accuracy, significantly reducing waste and production time. The automation of wood cutting not only ensures consistent product quality but also enables manufacturers to meet high demand with swift turnaround times. As the industry evolves, the ability to create intricate designs and custom products has become increasingly important, and CNC technology is at the forefront of this transformation.

One of the key benefits of integrating CNC wood cutting machines into manufacturing is their versatility. They can handle a diverse range of materials and designs, allowing businesses to expand their offerings without the need for multiple types of equipment. Additionally, the growing global market for CNC machinery, expected to reach $19.559 billion by 2032, signifies a strong shift toward automated solutions for efficiency and productivity. As manufacturers strive to remain competitive, adopting CNC technology will not only enhance operational capabilities but also drive innovation in wood product design and production processes.

Enhancing Precision and Consistency: How CNC Machines Improve Output Quality

In the realm of modern manufacturing, CNC wood cutting machines stand out for their ability to enhance precision and consistency in output quality. These advanced machines utilize computer numerical control technology, allowing for intricate designs and repeatable patterns with minimal human intervention. The adoption of such automation not only streamlines production processes but also significantly reduces errors, leading to higher efficiency and output quality. As manufacturers increasingly turn to these technologies, they realize the potential for creating complex wooden structures that meet the exacting demands of today's market.

Coupled with digital twin technology, manufacturers can further capitalize on CNC machines' advantages. A digital twin creates a virtual replica of the machine, enabling real-time monitoring and adjustments to ensure flawless operation. This innovation is essential in preventing collisions and guaranteeing that high-precision components are produced consistently. With the global precision engineering machines market projected to reach USD 29.16 billion by 2034, the integration of CNC technology and advanced automation methods such as digital twins solidifies their role as pivotal elements in enhancing manufacturing capabilities across various industries.

Cost Efficiency: Reducing Waste and Labor Costs with CNC Technology

In today's fast-evolving manufacturing landscape, CNC wood cutting machines stand out as key players in enhancing cost efficiency. These advanced machines significantly reduce waste by optimizing material usage and minimizing errors during the cutting process. As industries strive for better sustainability, the integration of CNC technology not only cuts down on labor costs but also promotes environmentally friendly practices through more precise operations.

Tip: To maximize cost savings with CNC machines, consider adopting a regular maintenance schedule. This practice ensures that machines operate at peak efficiency, reducing the likelihood of costly downtime and repairs.

The CNC machines market is set to experience remarkable growth, projected to reach USD 170.4 billion by 2033. This surge is driven by the industry's increasing reliance on automated processes, ensuring high-quality output while lowering operational costs. Consequently, businesses can reinvest those savings into innovation and expansion.

Tip: Explore software solutions that complement your CNC machines. Integrating design and manufacturing software can enhance workflow, leading to even greater efficiency and reduced production times.

Future Trends in CNC Wood Cutting: Innovations Shaping the Industry

In the rapidly evolving landscape of modern manufacturing, CNC wood cutting machines stand at the forefront of innovation, significantly boosting productivity across various industries. The emerging trends in digital manufacturing technology emphasize high precision and efficiency, leading to a substantial shift towards automated solutions. As manufacturers seek eco-friendly machinery that reduces operational costs, CNC machines are becoming indispensable tools that facilitate this transformation, allowing businesses to streamline their processes and enhance output quality.

Looking towards the future, innovations in CNC wood cutting technology are set to reshape the industry. Advancements in automation, artificial intelligence, and machine learning are paving the way for smarter manufacturing solutions that not only meet but exceed current expectations. As we approach 2024, it is crucial to recognize the significance of these innovations in optimizing production cycles and improving accuracy. The CNC wood cutting sector stands to benefit enormously from these trends, promising a more sustainable and efficient future for manufacturers worldwide.

Maximizing Efficiency: CNC Wood Cutting Machines in Modern Manufacturing

This chart illustrates the key efficiency metrics achieved by modern CNC wood cutting machines. The speed of operation, precision in cutting, cost efficiency, and energy consumption are critical factors that drive the adoption of these technologies in the manufacturing sector.

Related Posts

-

Essential Checklist for Choosing the Right Wood CNC Machine for Your Business Needs

-

Unlocking Precision: 7 Key Benefits of the Best CNC Machines for Your Business

-

Exploring Innovative Use Cases of Small CNC Machines for Metal Fabrication

-

Unlock Superior Manufacturing with the Best Smart CNC: A Premier Chinese Factory Solution

-

The Future of Advanced CNC Machine Technologies in Global Manufacturing

-

Discovering Quality Suppliers for the Best Mini CNC Machine in a Competitive Market

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska