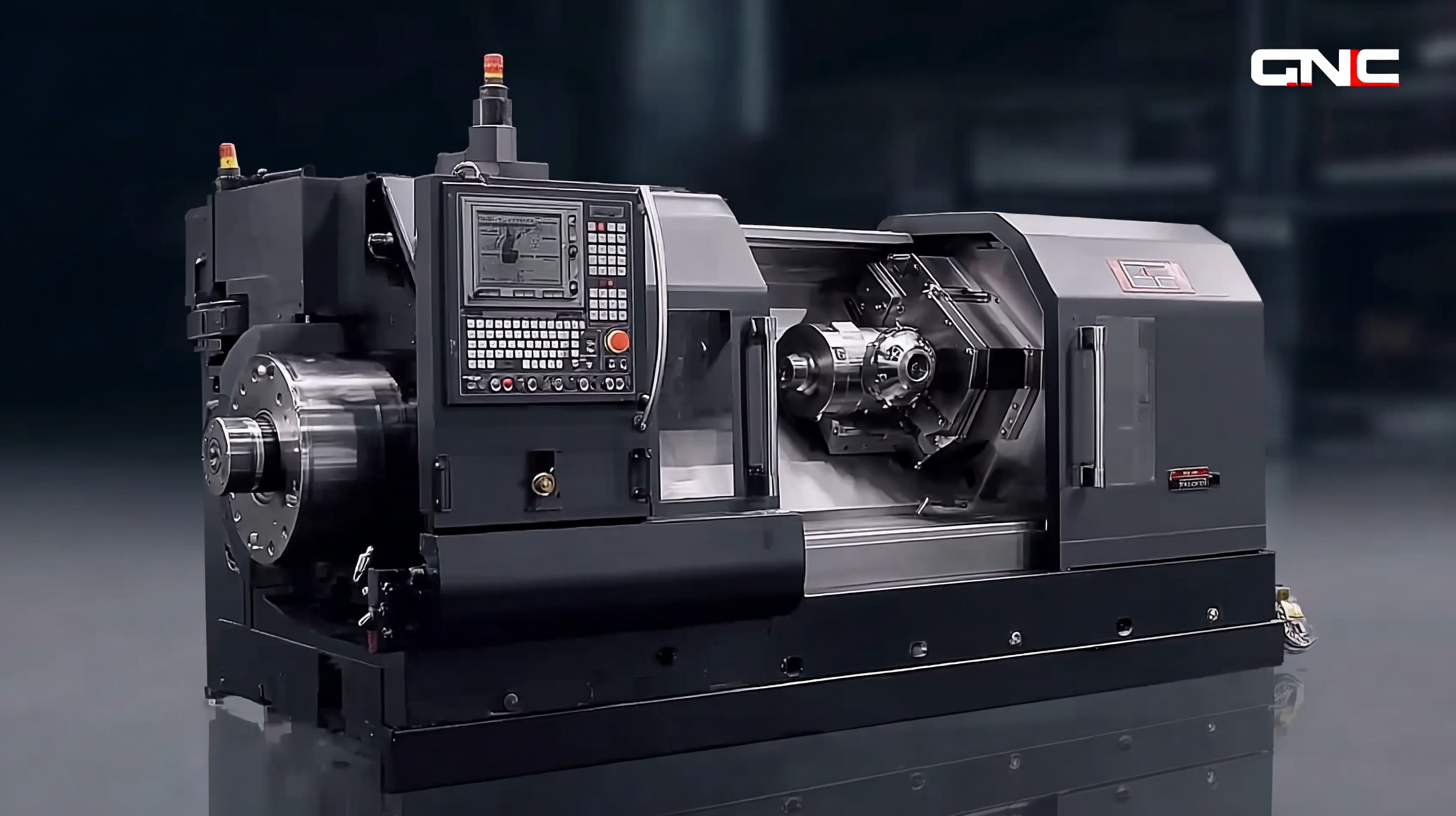

Global Sourcing Chinese Excellence: Why the Best CNC Lathe Machines Dominate World Markets

In the rapidly evolving landscape of manufacturing, the significance of the CNC lathe machine in global sourcing cannot be overstated. As we approach 2025, the trend towards automation and precision engineering underscores the dominance of Chinese manufacturers in the CNC lathe market. These machines not only embody technological excellence but also cater to a diverse range of industries, enhancing productivity and reducing operational costs. With advancements in materials, software, and machine capabilities, the best CNC lathe machines are set to play a pivotal role in shaping the future of manufacturing on a global scale. This blog will delve into the factors contributing to the supremacy of these machines, the anticipated technological developments, and their implications for industries worldwide.

The Rise of CNC Lathe Machines: A Paradigm Shift in Global Manufacturing

The landscape of global manufacturing is undergoing a significant transformation, largely driven by the rise of CNC lathe machines. This paradigm shift not only enhances precision and efficiency but also integrates advanced technologies like AI and IoT. As we approach 2025, the potential of industrial automation becomes clearer, with reports forecasting a considerable growth in related sectors. For instance, the global equipment as a service market is anticipated to surge at a staggering CAGR of 53% from 2024 to 2030, underscoring the increasing reliance on sophisticated machinery and services in manufacturing.

Tip: To stay ahead in this competitive environment, manufacturers should consider investing in the latest CNC technologies that offer connectivity and automation capabilities. The embracing of digital tools can reduce manual programming time by as much as 80%, streamlining production processes significantly.

Furthermore, as companies adopt these innovations, markets for specific tools like CNC tool grinders are expected to grow by a 6.3% CAGR through 2034, reflecting the rising demand for high-precision tooling. Emphasizing sustainability, the introduction of new technologies also paves the way for a circular economy, vital for addressing the environmental challenges that accompany rapid industrial growth.

Tip: Leveraging digital twin technology can optimize operations. Manufacturers that utilize these advancements will see improved efficiency and accuracy, positioning themselves as leaders in the rapidly evolving manufacturing sector.

Key Features That Make Chinese CNC Lathes Stand Out in the Market

Chinese CNC lathe machines have gained a significant foothold in global markets, primarily due to several key features that distinguish them from their competitors. One of the standout attributes is their precision and reliability, often attributed to the advanced manufacturing technologies utilized in their production. According to a report by MarketsandMarkets, the CNC machine tool market is projected to reach USD 115.3 billion by 2025, with a substantial portion of that growth fueled by Chinese manufacturers who have invested heavily in R&D. This commitment to excellence ensures that their machines not only meet but often exceed international quality standards.

Another critical factor contributing to the dominance of Chinese CNC lathes is their cost-effectiveness. A comparative analysis by Technavio indicates that the average price of Chinese CNC lathes is approximately 30% lower than that of competitors from Europe and North America. This price advantage, combined with high performance and durability, makes them appealing to businesses looking to optimize production costs without compromising quality. Furthermore, many of these machines are equipped with advanced features such as real-time monitoring and automated tool changes, which enhance productivity and reduce operational downtime, further solidifying their position in the global market.

Global Sourcing Chinese Excellence: Key Features That Make Chinese CNC Lathes Stand Out

| Feature | Description | Benefit |

|---|---|---|

| High Precision | Manufactured with advanced engineering techniques ensuring minimal tolerances. | Enhances product quality and reduces rework costs. |

| Cost-Effectiveness | Competitive pricing due to efficient manufacturing processes. | Allows businesses to maintain lower production costs. |

| Customization Options | Flexibility in designs to meet specific customer requirements. | Provides tailored solutions for diverse applications. |

| Advanced Technology | Utilizes state-of-the-art CNC technology for superior performance. | Increases machining efficiency and accuracy. |

| Robust Build Quality | Constructed using high-grade materials for durability. | Ensures long service life and reduced maintenance needs. |

| Support and Service | Comprehensive support including installation and maintenance. | Minimizes downtime and enhances operational efficiency. |

Impact of Advanced Technology on CNC Lathe Production Efficiency

The impact of advanced technology on CNC lathe production efficiency cannot be overstated. With the continuous evolution of machining techniques, manufacturers are now able to process difficult-to-machine alloys with greater ease and precision. Recent reviews highlight innovative lubricating and cooling methods, such as minimum quantity lubrication (MQL) and advanced cooling techniques, which significantly enhance machinability. This enables CNC lathes to operate at higher speeds and maintain tighter tolerances, thereby improving overall productivity.

Furthermore, the integration of digitalization, IoT, and artificial intelligence into CNC machining processes is revolutionizing the industry. These technologies allow for self-optimized machine cutting, greatly enhancing operational efficiency and reducing waste. As manufacturers increasingly adopt these advancements, the global CNC machine market is projected to grow substantially, driven by the need for more sophisticated and efficient machining solutions.

This transformation underscores a key trend in the industry: as technology continues to advance, the rise of CNC lathe machines will dominate global markets more than ever before.

Analyzing Market Trends: The Competitive Edge of Chinese Manufacturers in 2025

As we move toward 2025, the landscape of CNC lathe manufacturing is rapidly evolving, with Chinese manufacturers at the forefront. Their ability to combine innovative technology with competitive pricing allows them to dominate global markets. By utilizing advanced automation and high-quality materials, these manufacturers provide products that not only meet international standards but also offer excellent performance and durability.

Tips: To stay ahead in this competitive market, businesses should consider investing in advanced sourcing strategies. Collaborating with Chinese manufacturers who prioritize R&D can lead to higher-quality products and innovation. Additionally, leveraging supply chain efficiencies can reduce costs while enhancing delivery times.

Furthermore, the focus on sustainability is increasingly influencing market trends. Chinese companies are adopting eco-friendly practices and producing energy-efficient CNC lathe machines, appealing to environmentally conscious consumers. Companies seeking to partner with Chinese manufacturers should assess their sustainability practices and choose partners that align with their values.

Tips: Regularly review supplier sustainability reports to ensure compliance with global standards. Engaging suppliers in discussions about green practices can foster long-term relationships and improve corporate social responsibility.

Future Prospects: Growth Opportunities for CNC Lathe Machines in Global Markets

The global market for CNC lathe machines is projected to experience significant growth in the coming years, driven by advancements in manufacturing technology and increasing automation across various industries. According to a recent report by Grand View Research, the CNC lathe machine market is expected to reach USD 3.8 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.3% from 2019 to 2025. This surge is largely attributed to the rising demand for precise and efficient machining processes in sectors such as automotive, aerospace, and electronics.

Moreover, the ongoing trend of Industry 4.0, marked by the integration of smart technologies and IoT, is revitalizing the CNC lathe market. Manufacturers are increasingly incorporating sophisticated features such as predictive maintenance and data analytics into their machines, enhancing productivity and reducing downtime. According to a report by MarketsandMarkets, the smart manufacturing market is projected to grow from USD 190 billion in 2022 to USD 384 billion by 2027, presenting lucrative growth opportunities for CNC lathe machine producers. As Chinese manufacturers continue to innovate and improve their product offerings, they are poised to capture a significant share of this expanding global market, thereby cementing their position as leaders in CNC lathe production.

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska