7 Essential Tips for Optimizing Your Metal CNC Machine Performance

In the rapidly evolving landscape of manufacturing, optimizing the performance of a metal CNC machine has become paramount for industry leaders. According to Dr. James Anderson, a renowned expert in CNC technology, "The true potential of a metal CNC machine lies not just in its capabilities, but in how well it is utilized." This insight encapsulates the essence of effectively harnessing the power of these sophisticated machines to enhance productivity and precision.

The importance of fine-tuning various parameters in metal CNC operations cannot be overstated. Many manufacturers overlook simple adjustments that can lead to significant improvements in machining efficiency and product quality. Understanding the intricacies of your metal CNC machine, from tool selection and programming techniques to maintenance routines, is vital for achieving optimal performance.

As we delve into the essential tips for maximizing your metal CNC machine's capabilities, it's crucial to recognize that small changes can lead to substantial gains. By implementing strategic practices tailored to your operations, you can ensure that your equipment operates at its best, leading to improved output and reduced operational costs.

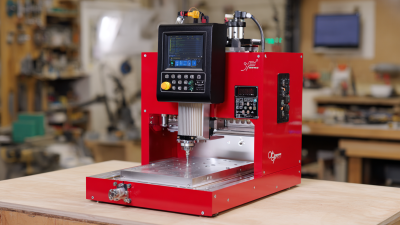

Understanding the Basics of Metal CNC Machine Operations

Understanding the basics of metal CNC machine operations is critical for optimizing performance and enhancing productivity. CNC (Computer Numerical Control) machines utilize computer systems to control machine tools, allowing for greater precision in metal fabrication. Reports from the International Federation of Robotics (IFR) indicate that the use of CNC machines in manufacturing has seen a steady increase, with a projected growth rate of 6% annually through 2025. This rise underscores the importance of understanding these operations to remain competitive in the industry.

Metal CNC machining involves the conversion of CAD (Computer-Aided Design) models into physical parts with high precision. A study by Grand View Research highlights that CNC machines can enhance productivity by approximately

30% while minimizing human error. Key aspects of operation include selecting the right tooling, understanding feed rates, and maintaining strict tolerances that align with production requirements. Proper training in these fundamentals ensures that operators can effectively troubleshoot issues, maintain machine health, and achieve optimal cycle times, ultimately leading to improved overall efficiency and quality in metalworking processes.

Selecting the Right Tools and Materials for Optimal Performance

Selecting the right tools and materials is crucial for optimizing the performance of your metal CNC machine. The choice of tools impacts not only the quality of the finished product but also the efficiency and longevity of the machine. When selecting cutting tools, consider factors such as the material of the tool, its geometry, and the intended application. For instance, carbide tools offer excellent wear resistance and are suitable for high-speed machining, whereas high-speed steel tools are cost-effective for lower-speed operations. It’s essential to match the tool's capabilities with the application requirements to maximize productivity and achieve precise results.

In addition to tools, the selection of materials plays a significant role in performance optimization. Different metals respond uniquely to CNC machining processes, affecting factors such as cutting speed, feed rate, and tool wear. For example, softer metals like aluminum can be machined more rapidly than harder materials like titanium or stainless steel. Understanding the material properties, including hardness, thermal conductivity, and machinability, will guide you in selecting the right combination for your projects. Moreover, ensuring proper material handling and storage can prevent defects and ensure consistent machining quality. By carefully considering both tools and materials, you can significantly enhance the efficiency and output of your metal CNC machining operations.

Adjusting Machine Settings for Enhanced Efficiency and Precision

Adjusting the machine settings on your CNC metalworking equipment is crucial for unlocking optimal efficiency and precision in your operations. One of the primary factors to consider is the spindle speed. By tailoring the spindle speed to match the material and tool geometry, you can significantly improve cutting performance and prolong tool life. For example, harder materials may require slower speeds, while softer metals can benefit from higher RPMs. Regularly monitoring and adjusting this setting based on the specific job requirements ensures that your CNC machine operates at peak efficiency.

Another key setting to optimize is the feed rate, which determines how quickly the tool moves through the material. An appropriate feed rate helps avoid issues like tool wear or breakage and can also impact the quality of the finished product. Experimentation combined with real-time data analysis can help identify the ideal feed rates for different machining tasks. Additionally, ensuring proper coolant application and adjusting it according to the operational speed not only helps manage heat but also enhances the finish quality of the workpiece. By carefully adjusting these critical machine settings, you ensure your CNC operations yield precise and efficient results consistently.

Regular Maintenance Practices to Extend Machine Lifespan

Regular maintenance is crucial for extending the lifespan of your metal CNC machine and ensuring optimal performance. One of the primary practices to adopt is a consistent cleaning routine. Dust, chips, and debris can accumulate in and around the machine, potentially affecting its functionality. By regularly cleaning the machine's components, including the spindle and tooling, you can prevent wear and tear and maintain precision in your operations. Additionally, using appropriate cleaning agents that are safe for your machine can help avoid any damage to sensitive parts.

Another essential maintenance practice involves lubrication and checking fluid levels. CNC machines rely on various fluids for smooth operation, from the coolant that aids in metal cutting to lubricants that reduce friction in moving parts. Regularly inspecting and replenishing these fluids ensures that your machine operates efficiently and reduces the risk of overheating or mechanical failures. Moreover, replacing worn-out components such as bearings or belts promptly can prevent more significant issues down the line, ultimately protecting your investment and enhancing the machine's reliability.

Implementing an organized maintenance schedule, complete with checklists and logs, can further support the longevity of your CNC machine. This approach not only helps in tracking the maintenance activities performed but also aids in identifying recurring issues, allowing for timely corrective measures. By prioritizing these practices, you can significantly improve the performance of your metal CNC machine while extending its usable life, leading to increased productivity and reduced downtime.

Troubleshooting Common Issues to Minimize Downtime

When it comes to optimizing the performance of metal CNC machines, addressing common issues is key to minimizing downtime. A recent report from the International Federation of Robotics highlights that unplanned downtime can cost manufacturers up to $260,000 a year, translating to a significant loss in productivity and revenue. To combat these challenges, operators should prioritize regular maintenance checks and implement robust troubleshooting procedures. Common issues such as tool wear, misalignment, and software glitches can often be identified and resolved quickly with consistent monitoring and a proactive approach.

Moreover, investing in real-time diagnostics can further enhance machine uptime. According to a study by the Manufacturing Technology Association, shops that employ predictive maintenance techniques experience up to 30% less downtime compared to those relying solely on reactive maintenance. This advancement allows for the timely identification of potential issues before they escalate, ensuring that CNC machinery remains operational. Operators are encouraged to familiarize themselves with the diagnostic capabilities of their machines and utilize software tools that can provide insights into performance metrics, ultimately leading to a more efficient machining process.

Related Posts

-

Exploring Innovative Alternatives to CNC Milling Machines for Your Manufacturing Needs

-

Unlocking Precision: How CNC Machines Revolutionize Manufacturing with 30% Efficiency Gains

-

Why Desktop CNC Machines Are Essential for Modern DIY Projects

-

The Future of Precision Engineering: Revolutionizing Manufacturing with the Best Desktop CNC Mills

-

How to Optimize CNC Milling for Enhanced Precision and Efficiency

-

Navigating the 2025 Technology Trends with the Best Small CNC Machine for Metal

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska