10 Essential Tips for Optimizing Your CNC Lathe Performance

In the highly competitive world of machining, maximizing the efficiency and performance of your CNC lathe is crucial. Industry expert John Smith, a seasoned CNC specialist, aptly states, "The key to precision lies in understanding your CNC lathe's capabilities and limitations." This statement underscores the importance of not only knowing how to operate a CNC lathe but also how to effectively optimize its performance for enhanced productivity and precision.

Applying the right techniques can significantly improve cycle times, reduce waste, and ensure that the output meets the highest quality standards. In this context, recognizing the various factors that contribute to the performance of a CNC lathe is essential. From tool selection and machining parameters to proper maintenance and alignment, each aspect plays a pivotal role in achieving optimal results.

This article presents ten essential tips that will guide CNC operators and machinists in enhancing their CNC lathe performance. By implementing these strategies, you can boost operational efficiency and ensure that your machining processes yield the best possible outcomes, allowing you to stay ahead in the rapidly evolving landscape of the manufacturing industry.

Understanding the Basics of CNC Lathe Operation and Performance

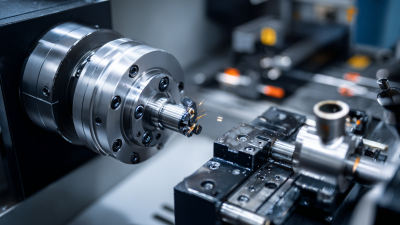

Understanding the basics of CNC lathe operation is crucial for maximizing performance and efficiency in machining processes. CNC lathes utilize computer numerical control to precisely manipulate the cutting tool, enabling highly accurate and repeatable production of complex parts. According to a report from MarketsandMarkets, the CNC machine market is expected to reach $117.00 billion by 2026, primarily driven by advancements in automation and the growing demand for precision engineering. This illustrates the significance of optimizing CNC lathe operation as manufacturers strive to improve productivity and reduce manufacturing costs.

Performance optimization begins with a thorough understanding of the machine's capabilities and limitations. Critical factors such as spindle speed, feed rate, and tooling must be carefully calibrated to match the material being machined. Research from the Manufacturing Innovation Institute indicates that optimizing these parameters can lead to a reduction in cycle times by up to 30% while enhancing surface finish quality. Additionally, keeping an eye on maintenance schedules and adopting a proactive approach towards machine upkeep can significantly reduce downtime, ensuring that the CNC lathe operates at its peak performance consistently. By mastering these fundamental aspects, manufacturers can achieve superior operational efficiency and cost-effectiveness in their CNC machining processes.

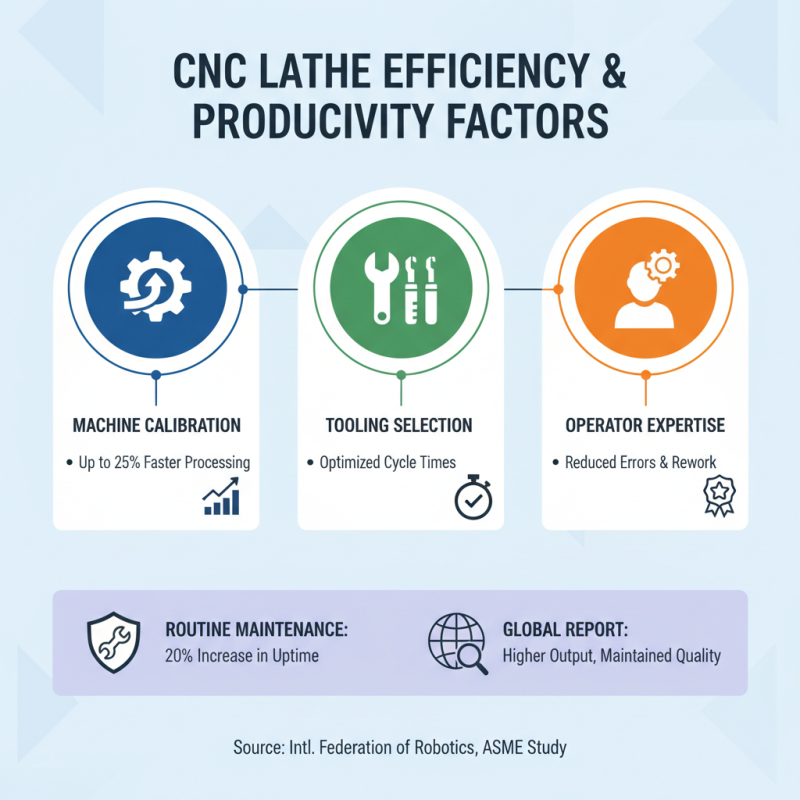

Key Factors Influencing CNC Lathe Efficiency and Productivity

The efficiency and productivity of CNC lathes are primarily influenced by several key factors, including machine calibration, tooling selection, and operator expertise. According to a report by the International Federation of Robotics, well-calibrated CNC machines can enhance processing speed by up to 25%. This optimization significantly reduces cycle times, allowing manufacturers to increase output without sacrificing quality. Proper maintenance of machines is also crucial; a study from the American Society of Mechanical Engineers indicates that routine maintenance can lead to a 20% increase in operational uptime, thus directly impacting overall productivity.

Another significant influence on CNC lathe performance is the choice of tooling. Research from the Manufacturing Performance Network reveals that selecting the right cutting tools can improve machining efficiency by up to 30%. The correct tools not only enhance material removal rates but also prolong tool life, resulting in fewer changes and less downtime. Additionally, operator training plays a pivotal role in optimizing performance. Skilled operators can make real-time adjustments and implement advanced techniques, contributing to a 15% increase in operational effectiveness as shown in findings from the National Institute of Standards and Technology. By focusing on these essential factors, manufacturers can significantly boost the productivity and efficiency of their CNC lathe systems.

Essential Maintenance Practices for Longevity of CNC Lathes

Proper maintenance practices are vital for ensuring the longevity and optimal performance of CNC lathes. Regular cleaning is a fundamental aspect of maintenance; dust, chips, and coolant residues can accumulate and hinder the machine's functionality. Implementing a routine cleaning schedule helps to remove these contaminants and prevents them from affecting the precision of machining operations. It is equally important to check and replace filters and coolant regularly, as this ensures the cooling system operates effectively, thereby extending the machine's life and enhancing its performance.

Another critical maintenance practice involves routine inspections of key components such as the spindle, bearings, and drives. Regularly checking for wear and tear allows operators to identify potential issues before they lead to costly downtime or repairs. Additionally, maintaining proper lubrication of moving parts is essential; this minimizes friction and ensures smooth operation. Following the manufacturer's recommendations regarding lubrication intervals and types of lubricants used contributes significantly to the machine's reliability. By adopting these essential maintenance practices, users can maximize the efficiency and lifespan of their CNC lathes, ensuring consistent productivity and reducing the risk of unexpected breakdowns.

10 Essential Tips for Optimizing Your CNC Lathe Performance

This chart showcases the essential maintenance practices for maximizing the performance and longevity of CNC lathes. The data represents the frequency of maintenance practices recommended for optimal lathe operation.

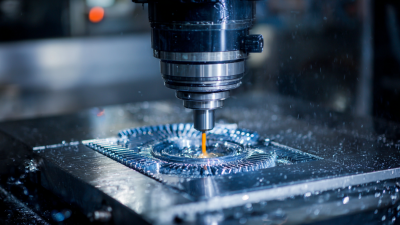

Advanced Tooling Techniques for Enhanced CNC Lathe Performance

Advanced tooling techniques play a crucial role in enhancing the performance of CNC lathes, significantly influencing productivity and precision in manufacturing processes. According to a recent industry report by the Association for Manufacturing Technology, implementing advanced tooling can lead to productivity improvements of up to 30%. One of the most effective strategies is the utilization of high-performance carbide inserts, which are engineered for extended tool life and superior chip removal rates. These inserts allow for higher cutting speeds and feed rates, enabling manufacturers to achieve optimal results while minimizing downtime and tool replacements.

Additionally, the integration of specialized coatings on tooling can further enhance performance. Research indicates that tools with advanced coatings, such as TiAlN, can reduce friction and improve heat resistance, thereby increasing tool longevity by as much as 50% compared to uncoated tools. This improvement not only lowers operational costs but also helps maintain consistent quality in machined components.

Furthermore, adopting modular tool systems facilitates quick tooling changes and adaptations, providing manufacturers with the flexibility needed to meet varying production demands efficiently. Overall, leveraging these advanced tooling techniques is essential for optimizing CNC lathe performance and sustaining competitive advantage in a rapidly evolving industry.

Monitoring and Analyzing CNC Lathe Performance Data for Improvement

Monitoring and analyzing CNC lathe performance data is crucial for enhancing machining efficiency and ensuring optimal productivity. By implementing effective data analytics strategies, operators can identify trends, pinpoint inefficiencies, and streamline operations. Utilizing software that collects real-time data from the lathe can provide valuable insights into machine utilization, cycle times, and tool wear. By examining these metrics, operators can make informed decisions about maintenance schedules, tooling changes, and process adjustments, ultimately leading to reduced downtime and improved output quality.

In addition to real-time monitoring, historical performance data plays a vital role in strategic planning. Analyzing past performance trends allows manufacturers to forecast future production needs and identify areas requiring optimization. For instance, by reviewing data over specific time frames, operators can discern patterns in machine performance related to various materials or machining parameters. This analysis can help in adjusting operational practices to maximize efficiency, such as optimizing feed rates or selecting appropriate cutting tools. By fostering a culture that prioritizes data analysis, manufacturers can achieve significant improvements in CNC lathe performance and overall production efficacy.

10 Essential Tips for Optimizing Your CNC Lathe Performance

| Tip | Description | Performance Metric | Current Value | Target Value |

|---|---|---|---|---|

| 1. Regular Maintenance | Ensure the lathe is regularly maintained to prevent breakdowns. | Downtime (%) | 5% | 1% |

| 2. Tool Calibration | Periodically calibrate tools to ensure accuracy. | Tool Wear Rate (mm/h) | 0.1 mm/h | 0.05 mm/h |

| 3. Coolant Usage | Use the correct coolant to improve tool life and surface finish. | Coolant Flow Rate (L/min) | 3 L/min | 4 L/min |

| 4. Feed Rate Adjustment | Adjust feed rates based on material type. | Feed Rate (mm/min) | 150 mm/min | 200 mm/min |

| 5. Monitor Vibration | Keep track of vibration levels to avoid tool failure. | Vibration Level (g) | 0.5 g | 0.2 g |

| 6. Optimize Tool Paths | Use software to optimize tool paths for efficiency. | Cycle Time (min) | 10 min | 8 min |

| 7. Regular Training | Train operators regularly on best practices. | Operator Efficiency (%) | 85% | 95% |

| 8. Data Analytics | Use data analytics tools to identify trends. | Data Points Collected | 1000 | 1500 |

| 9. Upgrade Software | Regularly update machining software for improvements. | Software Version | v1.0 | v2.0 |

| 10. Evaluate Production Metrics | Regularly review production metrics for continuous improvement. | Defect Rate (%) | 3% | 1% |

Related Posts

-

The Ultimate CNC Lathe Buying Guide: Key Factors for Global Procurement Success

-

Exploring Unique Features and Applications of Best CNC Manufacturing Solutions

-

Setting the Gold Standard: Industry Production Guidelines for the Best CNC Lathes

-

Global Buyers Choose China for Premium CNC Turning Machines with Unmatched Quality

-

Unlocking the Potential of CNC Turning for Precision Manufacturing Success

-

Mastering Precision with Small CNC Lathes for Your Next Project

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska