Why Desktop CNC Machines Are Essential for Modern DIY Projects

In today's fast-paced world, the DIY culture has been propelled into new heights, with enthusiasts seeking innovative ways to bring their creative ideas to life. One tool that has risen to prominence in this movement is the desktop CNC machine. These compact devices are transforming traditional manufacturing processes, allowing individuals to create intricate designs with precision and ease. As noted by industry expert, Mark Turner, a leading figure in CNC technology, "The desktop CNC is not just a tool; it’s a gateway to endless possibilities for makers and hobbyists alike."

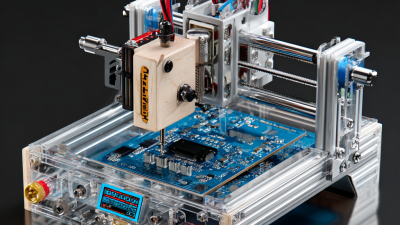

The emergence of desktop CNC machines has revolutionized the way DIY projects are approached. With their affordability and accessibility, these machines empower creators to engage in projects that were once limited to professional workshops. From personalized home decor to highly detailed prototypes, the versatility of desktop CNC technology enables users to explore their creativity without the constraints of conventional manufacturing methods.

As the demand for customized and bespoke items grows, desktop CNC machines are becoming an essential asset for modern DIY projects. They not only streamline the manufacturing process but also foster a culture of innovation and self-expression among makers. The integration of digital tools into the DIY realm signifies a new chapter where technology meets craftsmanship, giving rise to incredible creations that reflect the unique visions of individuals.

The Impact of Desktop CNC Machines on DIY Innovation

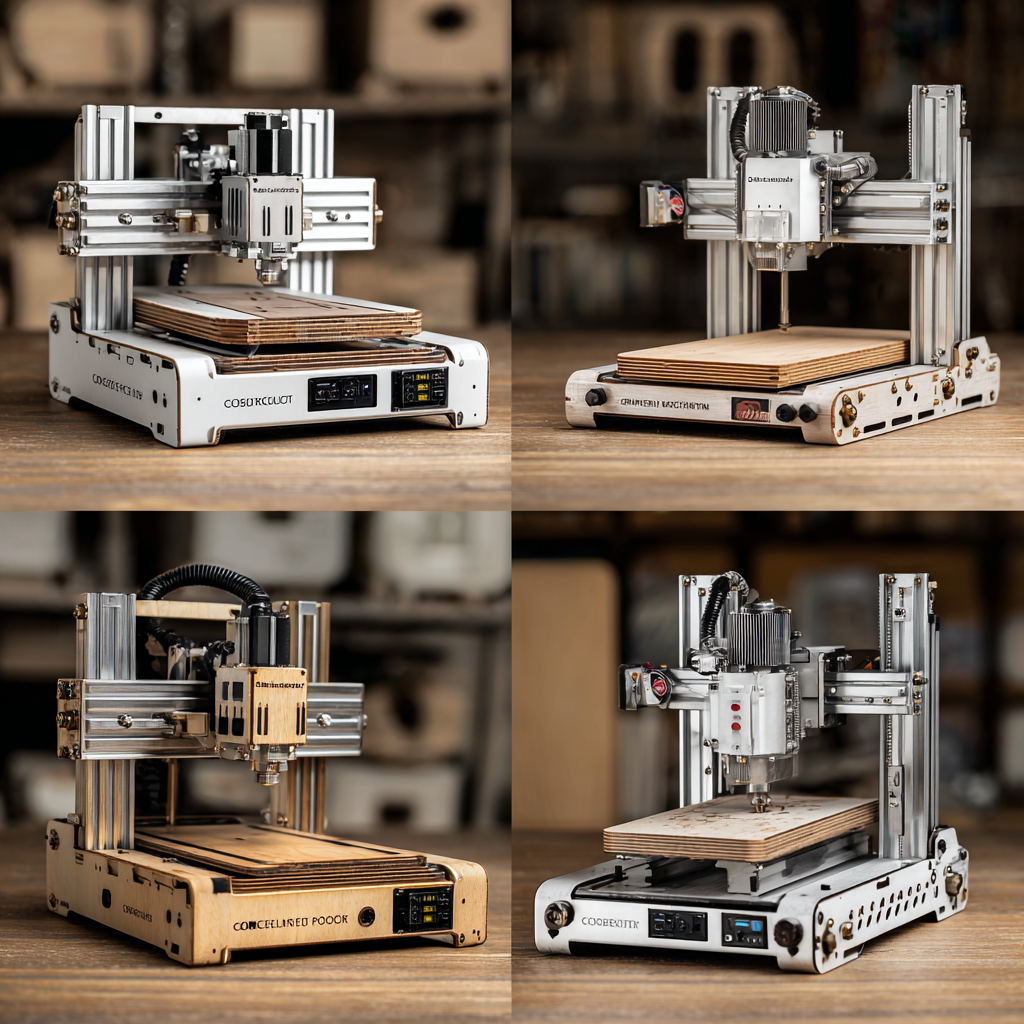

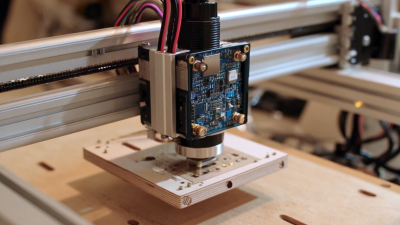

Desktop CNC machines have revolutionized the DIY landscape by providing precision and versatility that were once reserved for industrial applications. These compact devices allow hobbyists and innovators to turn their ideas into reality with incredible accuracy. The ability to create custom designs with ease has democratized manufacturing, empowering individuals to experiment with materials like wood, plastic, and metal in ways that were previously time-consuming or impossible.

One of the most significant impacts of desktop CNC machines on DIY innovation is their role in facilitating prototyping. Makers can quickly iterate on designs, refining their creations through multiple versions without the need for costly outsourcing. This rapid prototyping not only enhances creativity but also reduces the time it takes to go from concept to completion, encouraging a culture of experimentation and learning.

**Tip for Beginners:** Start with simple projects to build your skills. Experimenting with smaller, less complex designs will help you understand the capabilities of your CNC machine and boost your confidence.

**Tip for Design Software:** Familiarize yourself with CAD (Computer-Aided Design) software that suits your comfort level. Many user-friendly options are available for those new to design, allowing you to create and modify your projects efficiently.

By making advanced manufacturing accessible, desktop CNC machines are driving a new wave of creativity in the DIY community, enabling everyone from hobbyists to entrepreneurs to bring their visions to life.

Impact of Desktop CNC Machines on DIY Innovation

Key Features of Desktop CNC Machines for Hobbyists

Desktop CNC machines have become indispensable tools for hobbyists, offering precision and versatility across a range of DIY projects. One of the key features that make these machines stand out is their ability to create intricate designs with a high degree of accuracy. With various software options available, users can easily design and modify their projects digitally before executing them on the machine. This capability not only saves time but also reduces material waste, making it an economical choice for enthusiasts.

Desktop CNC machines have become indispensable tools for hobbyists, offering precision and versatility across a range of DIY projects. One of the key features that make these machines stand out is their ability to create intricate designs with a high degree of accuracy. With various software options available, users can easily design and modify their projects digitally before executing them on the machine. This capability not only saves time but also reduces material waste, making it an economical choice for enthusiasts.

Another essential aspect of desktop CNC machines is their compact size. Unlike traditional CNC machines that occupy significant space, desktop variants are designed to fit in small workshops or even home garages. This accessibility means that hobbyists can engage in complex manufacturing processes without needing a dedicated space. Additionally, many models incorporate user-friendly controls and tutorials, making them suitable for individuals with varying levels of experience. As a result, these machines empower creators to bring their ideas to life with ease, further fueling the DIY movement.

Step-by-Step Guide: Integrating CNC Machines into Your Projects

Integrating CNC machines into your DIY projects can significantly enhance the quality and precision of your work. To begin, familiarize yourself with the TIA Portal, a versatile platform designed for engineering innovative machines. Utilizing such tools allows you to streamline processes and optimize design workflows, ensuring that your CNC projects benefit from the latest automation technologies. This is especially crucial in today's fast-paced maker environment, where efficiency can set your project apart.

Next, focus on the practical application of your CNC machine. Begin by defining the project scope and selecting appropriate materials that suit your design needs. Consider exploring recent trends in DIY CNC projects, which offer numerous profitable and creative ideas for makers looking to start their CNC business. Ensure that your machine is well-calibrated and compatible with essential CAD/CAM software, which will enable smooth interoperability and precise toolpath generation. By following these steps, you can successfully integrate CNC technology into your DIY endeavors, elevating your projects and achieving exceptional results.

Cost-Effectiveness of Desktop CNC Solutions for DIY Enthusiasts

The rising popularity of desktop CNC machines among DIY enthusiasts can be attributed largely to their cost-effectiveness. With the projected market value of desktop CNC milling machines expected to reach $1.2 billion by 2024 and a remarkable growth rate of 9.2% from 2026 to 2033, it is clear that these tools are becoming increasingly accessible. This affordability allows hobbyists and small businesses to engage in precision manufacturing without the high overhead associated with traditional machinery.

Moreover, desktop CNC machines provide a versatile solution for various DIY projects, enabling users to create intricate designs and prototypes with ease. The integration of advanced technology into compact machines means that DIY enthusiasts can achieve professional-grade results right from their home workshops. As the demand for custom, handcrafted products continues to rise, the cost-effectiveness and efficiency of desktop CNC solutions make them an essential resource for anyone looking to elevate their crafting capabilities.

Future Trends: Advancements in Desktop CNC Technology by 2025

The future of desktop CNC technology is poised for remarkable advancements by 2025, driven by the increasing demand for efficiency and precision in DIY projects. According to a recent industry report, the global CNC machine market is projected to reach $100 billion by 2025, with a significant portion of this growth attributed to the rising popularity of desktop models among hobbyists and small businesses. These machines are becoming indispensable tools, offering users the ability to create intricate designs and prototypes quickly and with minimal material waste.

Simultaneously, emerging technologies such as 3D food printing are making waves in various sectors, paralleling the ongoing innovations in desktop CNC machines. The food printing market alone is expected to grow at a CAGR of 45% over the next few years, as it opens new avenues for creativity in culinary arts and personalization. As these technological advancements advance, they not only boost productivity but also transform the landscape of DIY projects, allowing creators to push the boundaries of what is possible. The convergence of these technologies underscores the essential role of desktop CNC machines in shaping the future of manufacturing and craftsmanship.

Related Posts

-

Excellence in Manufacturing from China Bringing the Best Mini CNC Machines to the World

-

20 Best Features of the Best CNC Wood Cutting Machine

-

2025 Top 5 Small CNC Machines for Metal: Discover the Best Precision Tools for Metalworking

-

Discovering Quality Suppliers for the Best Mini CNC Machine in a Competitive Market

-

Shaping the Future of CNC Machines at the 138th Canton Fair in 2025

-

Digital Revolution in Manufacturing Discover the Best Router CNC for Your Needs

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska