Digital Revolution in Manufacturing Discover the Best Router CNC for Your Needs

The digital revolution in manufacturing is transforming the way products are designed and produced, with technologies like router CNC playing a pivotal role in this evolution. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025, growing at a CAGR of 7.5%. This surge signifies the increasing adoption of computer numerical control systems across various industries, as manufacturers seek precision, efficiency, and scalability in their operations.

As leading factories in China adopt these advancements, they are setting new standards for excellence in manufacturing, showcasing the capabilities of high-quality router CNC machines. This blog aims to guide you in discovering the best router CNC options to meet your specific needs, ensuring you remain competitive in this rapidly evolving landscape.

As leading factories in China adopt these advancements, they are setting new standards for excellence in manufacturing, showcasing the capabilities of high-quality router CNC machines. This blog aims to guide you in discovering the best router CNC options to meet your specific needs, ensuring you remain competitive in this rapidly evolving landscape.

Advantages of CNC Routers in Modern Manufacturing Processes

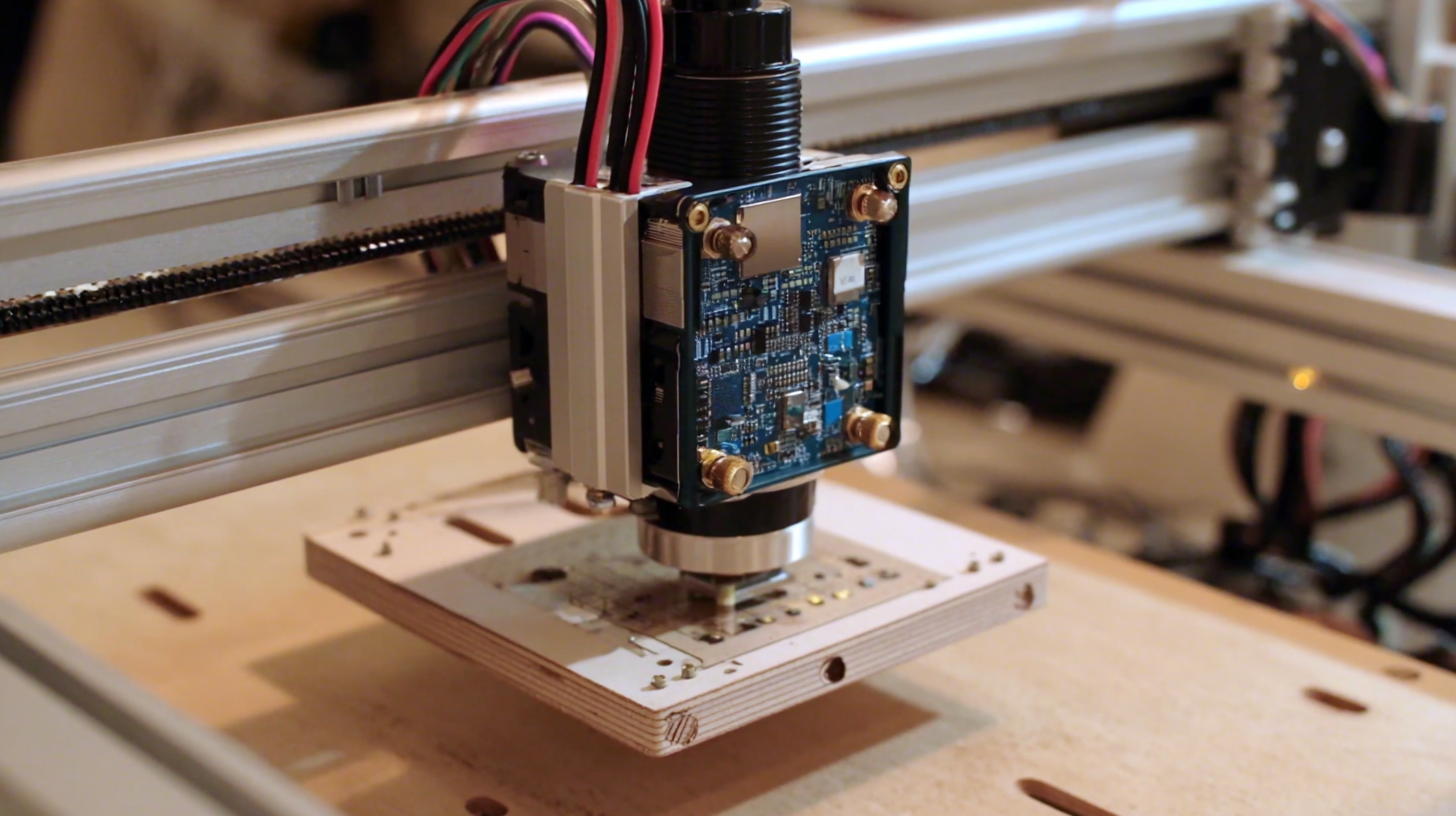

The digital revolution in manufacturing has profoundly transformed the way businesses operate, especially with the incorporation of advanced technologies such as CNC routers. In modern manufacturing processes, CNC routers bring numerous advantages that enhance efficiency and precision. They allow for intricate designs and automation, significantly reducing the time required for production. This level of automation not only improves operational speed but also minimizes human error, leading to higher overall product quality.

The digital revolution in manufacturing has profoundly transformed the way businesses operate, especially with the incorporation of advanced technologies such as CNC routers. In modern manufacturing processes, CNC routers bring numerous advantages that enhance efficiency and precision. They allow for intricate designs and automation, significantly reducing the time required for production. This level of automation not only improves operational speed but also minimizes human error, leading to higher overall product quality.

For companies striving to optimize their manufacturing capabilities, investing in the right CNC router is crucial. The market offers various options, but selecting a router that aligns with specific production needs can be the difference between success and inefficiency. Features such as versatility, ease of use, and compatibility with different materials should be taken into consideration. As manufacturers adopt these advanced tools, they experience shifts in productivity and innovation, driving the industry into a new era where digital and traditional manufacturing coexist harmoniously.

Key Features to Look for in a High-Quality CNC Router

When it comes to choosing the best CNC router for your manufacturing needs, focusing on key features can make a significant difference in the quality and efficiency of your projects. One of the most important considerations is the router's power and speed. A higher power rating will allow you to work with a broader range of materials, while adjustable speed settings provide flexibility for various applications. Make sure to select a router that matches your material specifications for optimal results.

Another crucial feature is the working area size. Depending on the scale of your projects, you'll want a CNC router that offers enough space for your workpieces. This is especially important if you plan to handle larger materials. Additionally, precision and accuracy are vital in manufacturing, so look for routers with advanced technology like closed-loop systems that enhance cutting precision.

Top Chinese Manufacturers Leading the CNC Router Market

The CNC router market is seeing significant transformation, driven by leading Chinese manufacturers. As the demand for automation and precision continues to grow, these companies are stepping up to offer innovative solutions that cater to various woodworking and manufacturing needs. With China's production capabilities, it's no surprise that they are at the forefront of the global CNC router industry, producing an increasing number of machines that combine efficiency with advanced technology.

When selecting a CNC router, consider the materials you will be working with and your specific projects. Different routers are designed for various applications, ranging from intricate carvings to heavy-duty milling. Additionally, investing in a machine with robust software support can enhance your operational capabilities.

Another tip is to analyze the after-sales support and warranty options provided by manufacturers. This can significantly impact your machine's longevity and your overall satisfaction with the purchase. Explore reviews and user feedback to find a router that not only meets your technical needs but also has solid customer service backing it up. As the market evolves, taking these factors into consideration will help you navigate your options effectively.

How CNC Routers Enhance Precision and Efficiency in Production

The rise of CNC routers in manufacturing has revolutionized the way products are designed and produced. These sophisticated machines combine advanced technology with precision engineering, offering manufacturers the ability to create intricate designs with remarkable accuracy. By utilizing computer numerical control, CNC routers eliminate human error and allow for consistent replication of products, ensuring that each piece meets stringent quality standards. This level of precision enhances the overall production process, making it possible to tackle complex projects that would be nearly impossible with traditional methods.

Efficiency in production is another significant advantage of CNC routers. These machines can operate continuously, significantly increasing output while reducing lead times. They enable manufacturers to optimize their workflow by automating tasks, allowing skilled workers to focus on more creative and strategic aspects of production. Additionally, the versatility of CNC routers means they can work with a wide variety of materials, from wood to metal, making them an invaluable asset in diverse industries. As businesses seek to enhance their competitive edge, investing in a high-quality CNC router can be a game-changer, streamlining operations and elevating product quality.

Digital Revolution in Manufacturing: Discover the Best Router CNC for Your Needs

| Feature | Value |

|---|---|

| Max Cutting Speed | 6000 mm/min |

| Diameter of Spindle | 80 mm |

| Working Area (X, Y, Z) | 1500 x 3000 x 200 mm |

| Precision | 0.01 mm |

| Control Software | Compatible with various CAD/CAM |

| Power Supply Requirement | 220V AC, 50Hz |

| Material Compatibility | Wood, Acrylic, Aluminum |

| Weight | 500 kg |

| Warranty | 2 Years |

Future Trends in Digital Manufacturing and CNC Technology

The global CNC machine market is poised for substantial growth, expected to surge from $101.22 billion in 2025 to approximately $195.59 billion by 2032, reflecting a robust compound annual growth rate (CAGR) of 9.9% during this forecast period. This growth is largely driven by the rising adoption of automation and robotics in various manufacturing sectors, as companies seek to enhance efficiency and productivity. The integration of Computer Numerical Control (CNC) technology is increasingly becoming a cornerstone of the digital revolution in manufacturing, transforming traditional processes and paving the way for advanced solutions.

As we delve deeper into the future trends in digital manufacturing, technologies such as 3D printing are emerging as key drivers within the automotive industry. Alongside the Industrial 4.0 revolution, 3D printing has positioned itself as a pivotal technology, enabling manufacturers to produce complex components with reduced waste and shorter lead times. Furthermore, the ongoing advancements in materials, including titanium and other composites, suggest that the potential market for 3D printing could reach unprecedented heights, fundamentally reshaping the landscape of manufacturing in the coming years. With these innovations, businesses must stay ahead by evaluating the best CNC router options tailored to their specific needs, ensuring they capitalize on the opportunities presented by modern manufacturing technologies.

Digital Revolution in Manufacturing: CNC Router Usage Trends

This chart illustrates the percentage of CNC router usage across various application areas in the manufacturing sector, highlighting the dominance of woodworking and the growing interest in metalworking and prototyping.

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska