Top CNC Turning Techniques for Precision Machining in Modern Manufacturing

In the ever-evolving landscape of modern manufacturing, precision machining stands out as a pivotal factor for competitiveness and efficiency. Among the myriad techniques employed, CNC turning has gained prominence for its ability to produce intricate components with exceptional accuracy and repeatability. According to a recent industry report by the Association for Manufacturing Technology, CNC turning operations account for approximately 30% of all CNC machining processes in the U.S., showcasing its significance in the manufacturing sector.

Industry expert Dr. Elizabeth Tran, a leading voice in precision engineering, emphasizes the critical role of CNC turning in the production of high-tolerance parts: "CNC turning not only streamlines manufacturing processes but also enhances the overall quality and consistency of machined components." With the demand for precision components in sectors ranging from aerospace to medical devices, adopting advanced CNC turning techniques has never been more essential. This introduction of cutting-edge tools and methodologies in CNC turning enables manufacturers to meet stringent quality standards while optimizing operational efficiency, paving the way for innovations in design and production.

Understanding CNC Turning: Key Principles and Technologies

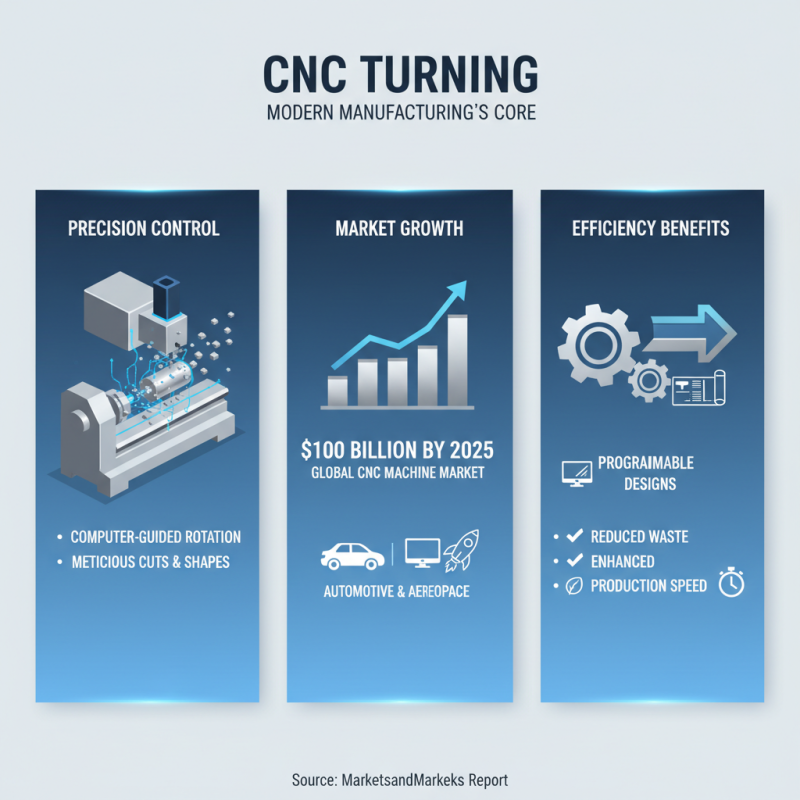

CNC turning is a vital process in modern manufacturing, characterized by its ability to deliver high precision and efficiency. At the core of CNC turning lies the principle of precision control, where computer numerical control systems guide the rotation of materials to achieve meticulous cuts and shapes. According to a report by MarketsandMarkets, the CNC machine market is expected to reach $100 billion by 2025, highlighting the increasing reliance on this technology across various industries, including automotive and aerospace. The ability to program complex designs and automate production processes allows manufacturers to not only reduce waste but also enhance production speed.

Key technologies underpinning CNC turning include advanced materials, sophisticated tooling, and software innovations. The integration of CAD/CAM systems enables seamless transition from design to manufacturing, ensuring each component is produced to exact specifications. Additionally, the implementation of real-time monitoring systems has improved process efficiency, reducing downtime by up to 20%, as reported by the International Journal of Advanced Manufacturing Technology. This synergy of principles and technologies makes CNC turning an indispensable part of modern precision machining, enabling manufacturers to meet the increasingly stringent demands of quality and speed in today's competitive landscape.

Essential Tools Used in CNC Turning for Precision Machining

CNC turning is a vital process in precision machining, allowing manufacturers to create complex shapes and parts with high accuracy and efficiency. Fundamental to this process are several essential tools that enhance effectiveness and precision. The key components include turning tools, tool holders, inserts, and the CNC lathe itself. According to a recent industry report, the global CNC machine market is projected to reach USD 100 billion by 2024, emphasizing the increasing reliance on advanced machining techniques to meet diverse manufacturing needs.

Turning tools come in various geometries and materials, such as carbide and high-speed steel, which are chosen based on the specific requirements of the operation. Tool holders serve as adapters that interface between the CNC lathe and the cutting tool, ensuring stability and precision during machining. Inserts, often interchangeable, are critical for maximizing tool life and minimizing downtime; they can be tailored for specific materials, drastically improving machining effectiveness. The right set of tools can lead to a reduction of machining time by 30%, as highlighted in machining optimization studies, showcasing potential productivity gains across industries that utilize CNC turning technology effectively. The integration of these essential tools into CNC turning processes not only enhances precision but also contributes to sustainable manufacturing practices by reducing waste and energy consumption.

Top CNC Turning Techniques for Precision Machining in Modern Manufacturing

| Technique | Description | Essential Tools | Applications |

|---|---|---|---|

| Slant Bed Turning | Utilizes a slanted bed design to enhance chip removal and cutting tool access. | CNC Lathe Machine, Carbide Cutting Tools | Automotive, Aerospace Components |

| Live Tooling | Enables simultaneous milling and turning operations for complex parts. | CNC Turning Center, Live Tool Holders | Medical Devices, Precision Parts |

| CNC Swiss Turning | Suitable for producing small, complex, and high-precision parts. | Swiss CNC Lathe, Guide Bushings | Watch Parts, Aerospace Fasteners |

| Hard Turning | A process to machine hardened materials, replacing grinding operations. | CNC Turning Machine, CBN Cutting Tools | Bearing Rings, Gears |

| Multi-Axis Turning | Facilitates the machining of complex geometries through coordinated motion. | 5-Axis CNC Lathe, Advanced Tooling Systems | Aerospace Components, Custom Tooling |

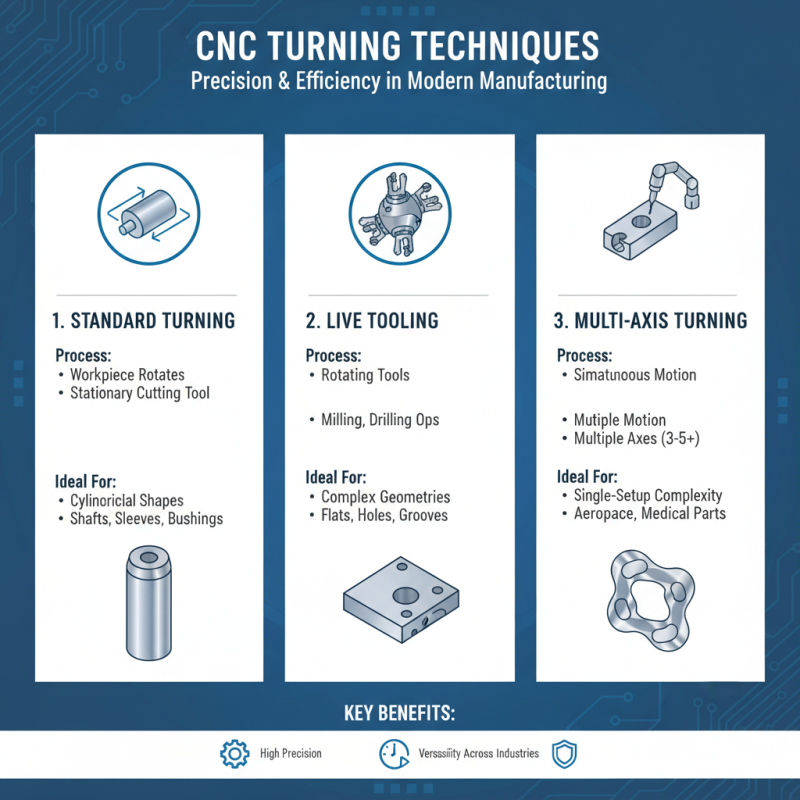

Common CNC Turning Techniques and Their Applications in Manufacturing

CNC turning is an essential process in modern manufacturing, providing high levels of precision and efficiency. Several common techniques are utilized in CNC turning, each serving specific applications that are vital in various industries. One prominent technique is the standard turning process, where the workpiece is rotated against a stationary cutting tool. This method is ideal for creating cylindrical shapes and is widely used in producing shafts, sleeves, and bushings.

Another technique is facing, which involves cutting flat surfaces on the end of the workpiece. This is crucial for ensuring proper fit and alignment in assembly applications. Additionally, threading is a common CNC turning technique, allowing for the creation of helical grooves for fasteners. The versatility of CNC turning makes it suitable for both prototyping and mass production, enhancing manufacturing processes in sectors such as aerospace, automotive, and medical devices.

**Tips**: When choosing a CNC turning technique, consider the material properties and the final design requirements. Factors such as part geometry and tolerance levels play a significant role in determining the most effective method. Additionally, regular maintenance of CNC machines can greatly improve precision and extend the lifespan of your equipment, ensuring that you achieve the highest quality outputs in your manufacturing processes.

Benefits of CNC Turning in Modern Precision Manufacturing Processes

CNC turning is a pivotal technology in modern precision manufacturing, offering numerous benefits that enhance operational efficiency and product quality. One of the primary advantages of CNC turning lies in its ability to produce intricate geometries with high precision. By leveraging computer-controlled lathes, manufacturers can achieve tight tolerances that are essential for components used in various industries, from automotive to aerospace.

The automation inherent in CNC turning processes significantly reduces the potential for human error, leading to more consistent and repeatable results. Moreover, the machine’s capability to run continuously increases productivity, thus allowing manufacturers to meet heightened demands in shorter timeframes. This is particularly beneficial in today's fast-paced market, where efficiency can be a game-changer.

Tip: To maximize the benefits of CNC turning, ensure regular maintenance of machinery. Keeping equipment in optimal condition not only extends its lifespan but also ensures that precision levels remain high throughout the production cycle. Additionally, investing in skilled operators who understand CNC programming can also lead to better outcomes and innovation in product design.

Another key benefit of CNC turning is its versatility. With various materials and sizes, CNC turning accommodates a wide range of applications, making it a go-to choice for manufacturers facing diverse project requirements. The adaptability of CNC turning enables quicker adjustments and prototyping, allowing businesses to innovate without significant delays.

Tip: Implementing advanced software for CNC operations can streamline the process even further. Consider using simulation tools to visualize the machining process before actual production, which helps identify potential issues and optimize tool paths, ultimately saving time and resources.

Future Trends in CNC Turning: Innovations and Advancements

In the rapidly evolving landscape of modern manufacturing, CNC turning is experiencing remarkable innovations that promise to enhance precision and efficiency. One of the most significant trends is the integration of advanced automation and robotics into CNC turning processes. This shift is streamlining production lines, minimizing manual intervention, and allowing for more consistent quality control. As machine tools become increasingly automated, manufacturers can expect reduced cycle times and improved productivity, ultimately leading to lower operational costs and higher output.

Moreover, the advent of smart technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), is transforming CNC turning practices. IoT-enabled machines can monitor operational parameters in real-time, providing valuable data for predictive maintenance and operational optimization. This connectivity facilitates better decision-making, enabling manufacturers to adapt quickly to changing demands and improve their overall process efficiency. AI algorithms can also enhance programming and toolpath optimization, allowing for more complex geometries and tighter tolerances than ever before, thereby pushing the limits of what is possible in precision machining.

Top CNC Turning Techniques for Precision Machining

Related Posts

-

Global Buyers Choose China for Premium CNC Turning Machines with Unmatched Quality

-

Unlocking the Potential of CNC Turning for Precision Manufacturing Success

-

10 Essential Tips for Optimizing Your CNC Lathe Performance

-

Unmatched Excellence in Best CNC Metal from Leading Chinese Manufacturers

-

Revolutionizing Production Efficiency with Advanced CNC Metal Machining Techniques

-

Exploring Innovative Use Cases of Small CNC Machines for Metal Fabrication

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska