How to Choose the Right Desktop CNC for Your DIY Projects

As the DIY community continues to grow, so does the demand for precision tools that can elevate creative projects. Desktop CNC (Computer Numerical Control) machines have become invaluable assets for hobbyists and professionals alike, enabling intricate designs and automation in the crafting process. According to a report from ResearchAndMarkets, the global CNC machine market is projected to reach approximately $100 billion by 2025, with a significant segment attributed to desktop CNC systems catering to small-scale production. These compact machines provide accessibility to precision machining previously reserved for industrial settings, allowing users to cut, carve, and mill materials ranging from wood to metal in their own workshops. By understanding the key features and specifications of various desktop CNC options available on the market, you can ensure that you select the right model to meet your specific project needs and enhance your DIY capabilities.

Understanding CNC Technology: Overview of Desktop CNC Machines and Their Benefits

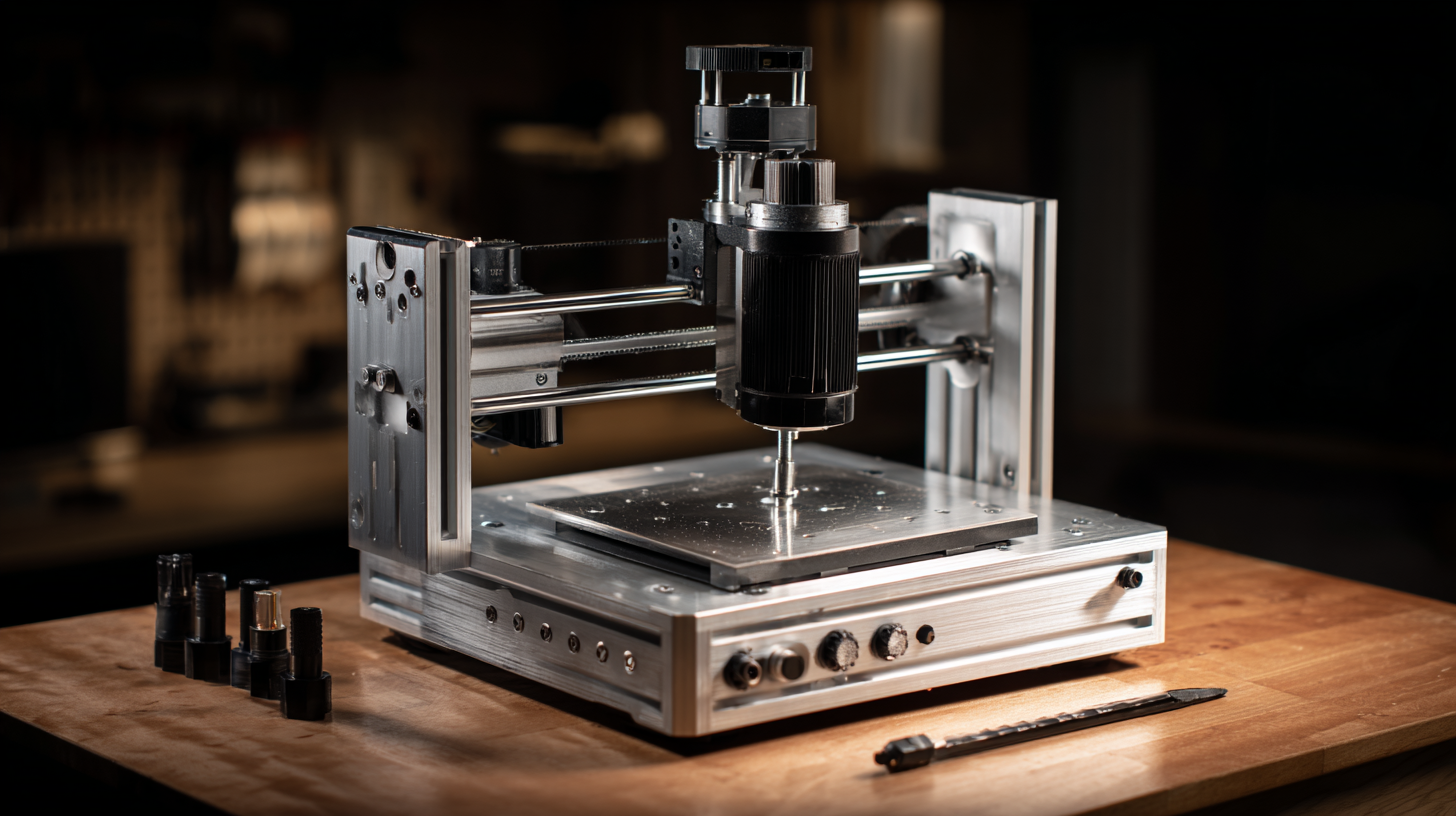

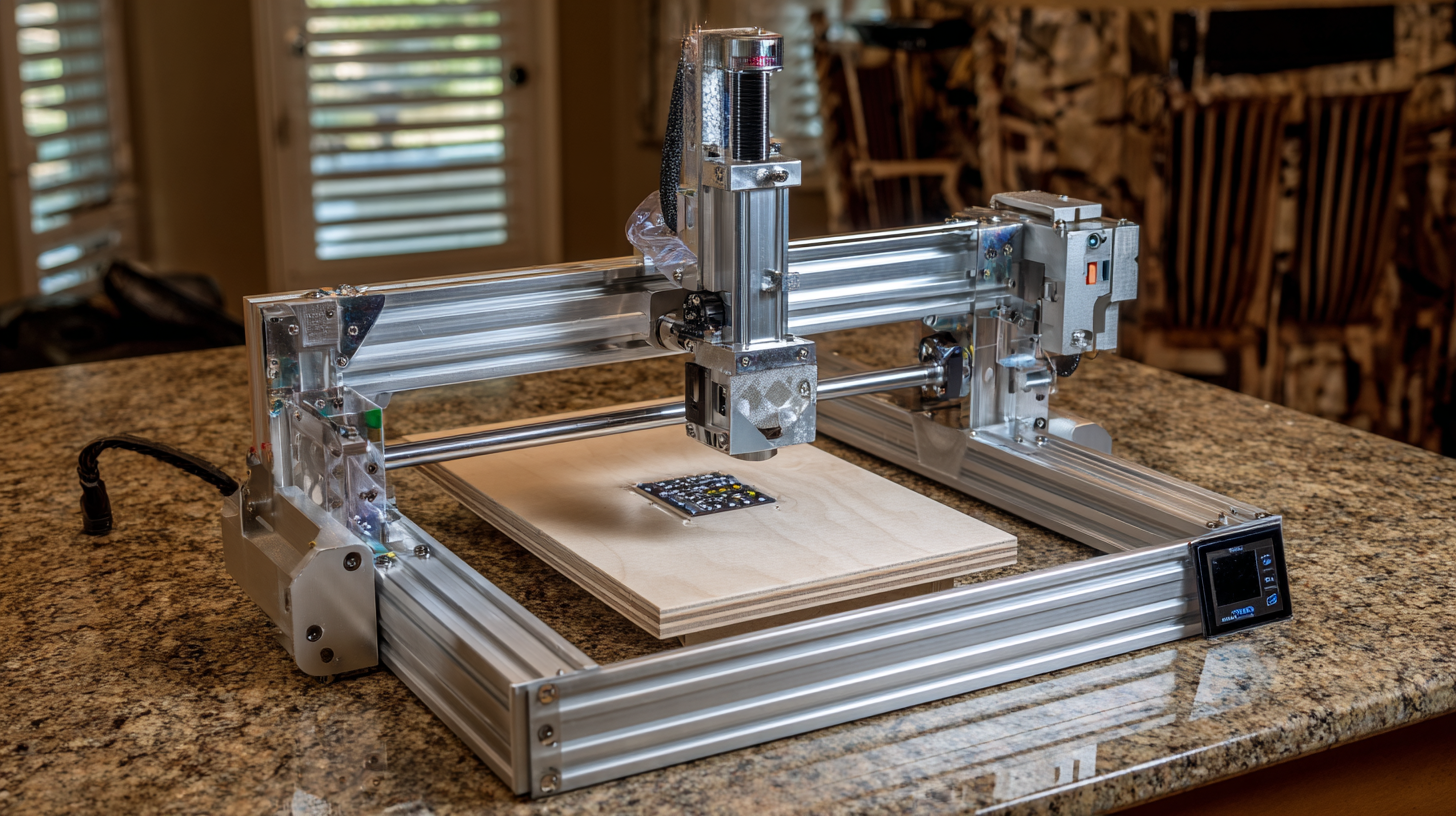

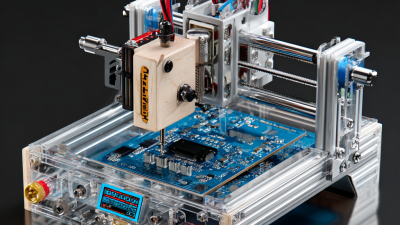

When delving into the world of DIY projects, understanding CNC technology is crucial for selecting the right desktop CNC machine. These devices are designed to take precise digital designs and translate them into physical products, making them invaluable for makers, hobbyists, and small businesses alike. Desktop CNC machines come in various types, such as milling machines, laser cutters, and 3D printers, each suited for different applications. The benefits they offer include enhanced accuracy, the ability to create complex designs, and the efficiency of producing multiple copies.

Tip: Before purchasing a desktop CNC machine, assess the materials you plan to work with. Some machines are better suited for wood, while others excel with metals or plastics.

Another important factor is the software compatibility. Many CNC machines require specific software to create and send designs to the machine, so ensure that the machine you select is compatible with your design tools.

Tip: Look for user reviews and community support for the CNC machine you are considering. A strong support network can be invaluable when you're troubleshooting or looking for project inspiration.

Key Features to Consider When Choosing a Desktop CNC for DIY Projects

When choosing the right desktop CNC machine for your DIY projects, it’s essential to consider several key features that can significantly impact your project outcomes. One of the foremost features is the machine’s precision and accuracy. For instance, many modern desktop CNC models provide cutting resolutions as fine as 0.01 mm, which is crucial for detailed work like engraving and intricate designs. This level of precision can elevate your DIY projects from simple crafts to professional-quality creations.

Another important feature to examine is the machine's versatility concerning various materials. Many top-rated CNC machines are capable of working with a diverse range of materials including wood, plastic, and even softer metals. This adaptability allows for a broader scope of projects, enabling hobbyists to create everything from custom furniture to unique art pieces. Additionally, ease of use is a critical factor. User-friendly designs, combined with intuitive software interfaces, ensure that even beginners can operate these machines effectively, making it easier to start and complete projects confidently.

Comparative Analysis of Popular Desktop CNC Models: Performance and Cost

When choosing the right desktop CNC machine for DIY projects, it's essential to conduct a comparative analysis of popular models based on their performance and cost. Recent reports indicate that the global desktop CNC market is projected to grow significantly, with particular interest in models that provide balance between affordability and advanced capabilities. For instance, data from industry analyses suggest that models with higher spindle speeds and precision manufacturing capabilities often result in better overall performance, making them more valuable for serious hobbyists and professionals alike.

In exploring cost-effectiveness, one must consider the long-term benefits associated with each model, including maintenance costs and the availability of replacement parts. As highlighted in numerous studies, including those examining fabrication techniques like microfluidics chip production, the initial investment can often be offset by the savings on materials and time efficiency. Thus, understanding the specifications and capabilities of each desktop CNC model—such as their build volume, supported materials, and ease of use—can guide users to make informed decisions that align with their project requirements and budget constraints.

Comparative Analysis of Popular Desktop CNC Models

Safety Standards and Best Practices for Operating Your Desktop CNC Machine

When operating a desktop CNC machine for your DIY projects, understanding safety standards and best practices is paramount. Implementing safety measures helps to minimize risks associated with the precision and power of these machines. One crucial aspect of safe operation is ensuring that all components, including pneumatic systems, are integrated with safety features. Properly configured safety PLCs can greatly enhance the operational reliability of CNC machines by automating responses to potential hazards.

In addition to installing safety PLCs, users should stay informed about the latest technologies that improve monitoring and safety in manufacturing. For example, AI-enhanced monitoring systems can offer real-time insights into machine operations, alerting users to any anomalies that could pose safety risks. Moreover, adhering to established guidelines, conducting regular maintenance, and wearing appropriate protective equipment are essential practices to safeguard against accidents while maximizing productivity in your projects.

Assessing Your Project Needs: Material Compatibility and Machine Specifications

When selecting a desktop CNC machine for your DIY projects, it's essential to assess your project needs carefully. Start by considering the types of materials you plan to work with. Different CNC machines are optimized for specific materials such as wood, plastic, or metal. For instance, if your projects predominantly involve softwoods or acrylics, a router-based CNC might suffice. However, for machining tougher materials like aluminum or brass, a machine with a higher rigidity and more powerful spindle is necessary. Understanding the material compatibility with the CNC machine will significantly influence your project's outcome and efficiency.

Machine specifications are equally critical to consider. Pay attention to parameters such as the spindle speed, cutting area, and tool compatibility. A larger cutting area provides versatility for bigger projects, while a high spindle speed ensures quicker cuts and finer details. Additionally, explore the type of control software that comes with the machine. A user-friendly interface can greatly enhance your workflow, especially if you are a beginner. Evaluating both material compatibility and machine specifications will guide you in choosing a CNC that not only meets your current project needs but also allows room for future creativity.

Related Posts

-

Ultimate Guide to Mastering Your First Desktop CNC Mill for Precision Engineering

-

Excellence in Manufacturing from China Bringing the Best Mini CNC Machines to the World

-

Discovering Quality Suppliers for the Best Mini CNC Machine in a Competitive Market

-

Exploring the Future of Best Milling Machines in 2025 Industry Trends and Innovations

-

The Future of Precision Engineering: Revolutionizing Manufacturing with the Best Desktop CNC Mills

-

Exploring Innovative Use Cases of Small CNC Machines for Metal Fabrication

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska