Why Choose a Milling Machine for Precision Engineering Projects?

In the evolving landscape of precision engineering, the choice of machinery plays a pivotal role in determining the success of projects. Among various tools available, the milling machine stands out for its versatility and accuracy in producing intricate parts with tight tolerances. As noted by Dr. James L. Turner, a leading expert in precision manufacturing, “The milling machine is the bedrock of modern fabrication, allowing engineers to realize complex designs with unmatched precision.”

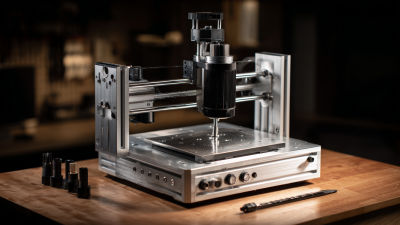

The significance of milling machines in engineering projects cannot be overstated. These machines enable professionals to transform raw materials into finely crafted components, making them indispensable in industries that require exceptional precision. From aerospace to automotive applications, the milling machine's ability to execute complex cuts and shapes is what sets it apart from other machining tools.

As we delve deeper into the reasons why milling machines should be the go-to choice for engineers, we will explore their advantages, including increased productivity, enhanced surface finish, and flexibility in handling various materials. This discussion will illuminate why investing in a milling machine is essential for staying competitive in the fast-paced realm of precision engineering.

Types of Milling Machines: An Overview for Precision Engineering

Milling machines are essential tools in precision engineering, offering a range of capabilities that cater to various industrial needs. There are several types of milling machines, including vertical, horizontal, and CNC milling machines, each designed to accomplish specific tasks with high accuracy. The global CNC milling machines market, valued at approximately $83.09 billion in 2024, is projected to grow significantly, reaching $103.92 billion by 2032, driven by the increasing adoption of Industry 4.0 technologies and smart manufacturing advancements.

Tips: When selecting a milling machine for your precision project, consider the type of material you will be working with and the level of precision required. Additionally, evaluate the machine's features, such as automation capabilities and ease of programming, to ensure it aligns with your production goals.

The advancements in milling technology, particularly in end milling machines, have further enhanced their applicability in precision metalworking, with the market expected to see continued growth. Understanding the specific type of milling machine and its functionalities will help engineering professionals make informed decisions that can lead to improved efficiency and output in their projects.

Tips: Always conduct thorough market research to identify the latest innovations in milling machines. Look for models that not only fit your current requirements but also have the potential for scalability as your production needs evolve.

Key Advantages of Using Milling Machines in Precision Engineering

In the realm of precision engineering, milling machines stand out as essential tools for achieving high accuracy in manufacturing processes. Their ability to remove material in a controlled manner allows for the creation of intricate components with tight tolerances. Among the key advantages of using milling machines is their versatility; they can work with a variety of materials, including metals, plastics, and composites, making them invaluable in various applications from automotive to aerospace.

Tip: When selecting a milling machine, consider the specific requirements of your project, such as material type and desired precision levels. This will help ensure that the machine you choose can meet your production demands efficiently.

Additionally, milling machines offer a range of configurations, including vertical and horizontal models, which can enhance productivity and streamline workflow. With advancements in CNC technology, modern milling machines can incorporate automated features that further increase efficiency and reduce human error, making them a wise choice for businesses eager to embrace smart manufacturing practices.

Tip: Regular maintenance and calibration of milling machines can significantly extend their lifespan and maintain high precision levels. Establishing a routine check-up plan is crucial for sustaining optimal performance.

Why Choose a Milling Machine for Precision Engineering Projects?

This chart illustrates the key advantages of using milling machines in precision engineering projects, highlighting their effectiveness in areas such as precision, versatility, efficiency, durability, and cost-effectiveness.

Comparative Analysis: Milling Machines vs. Other Machining Tools

Milling machines have emerged as essential tools in precision engineering, particularly when compared to other machining equipment. The global CNC machine market is anticipated to expand significantly, from $101.22 billion in 2025 to $195.59 billion by 2032, showcasing a strong compound annual growth rate (CAGR) of 9.9%. This robust growth reflects the increasing adoption of advanced machining techniques, where milling machines stand out for their ability to produce complex shapes with high accuracy.

In Europe, the machine tools market is projected to reach USD 47.75 billion by 2033, with Germany leading the charge, holding a 32.4% market share. This dominance underscores the importance of milling technology in the manufacturing landscape. Additionally, specialized sectors such as industrial food milling and rice milling are witnessing remarkable growth, with the industrial food milling machine market predicted to rise from USD 166.5 million in 2025 to USD 268.6 million by 2035. Such statistics highlight the versatility and increasing demand for milling machines across diverse applications, making them a preferred choice for precision engineering projects.

Why Choose a Milling Machine for Precision Engineering Projects?

| Machining Tool | Precision (mm) | Material Versatility | Speed of Operation | Ease of Use |

|---|---|---|---|---|

| Milling Machine | ±0.01 | High | Moderate | Easy |

| Lathe Machine | ±0.02 | Moderate | High | Moderate |

| CNC Machine | ±0.005 | Very High | Very High | Moderate |

| Band Saw | ±0.5 | Low | High | Easy |

Technological Innovations in Milling Machines for Enhanced Precision

The evolution of milling machines has brought forth numerous technological innovations that significantly enhance precision in engineering projects. As traditional machining methods give way to advanced digital manufacturing technologies, industries are experiencing notable productivity improvements. Reports indicate that the global micromachining equipment market is projected to grow from approximately USD 3.3 billion in 2024 to over USD 5.6 billion by 2033, underscoring the increasing reliance on precision tools in manufacturing processes.

One groundbreaking innovation is the introduction of advanced drilling and milling tools that allow for multifaceted operations from a single setup. For instance, modern milling machines can now execute drilling, milling, and countersinking processes seamlessly, minimizing the risk of imperfections such as blowouts. This not only boosts efficiency but also enhances the overall quality of the finished products, making them more precise and reliable.

Tips:

- When selecting a milling machine, prioritize models that offer multifunctional capabilities to save time and reduce handling errors.

- Regularly update your milling technology and software to stay ahead in the competitive landscape and ensure you’re leveraging the latest advancements for optimal precision.

Applications of Milling Machines in Various Precision Engineering Projects

Milling machines play a crucial role in various precision engineering projects across industries. Their versatility allows them to handle a wide range of materials, including metals, plastics, and composites, making them essential for creating intricate parts and components. In sectors such as aerospace, automotive, and medical device manufacturing, the precision afforded by milling machines ensures that even the most complex designs can be executed with accuracy and reliability.

With the growing demand for automation and efficiency in manufacturing processes, the global market for CNC machines, particularly milling machines, is projected to see significant growth. The increasing emphasis on precision engineering has led to a rise in the adoption of CNC milling technologies, enhancing production rates and reducing operational costs. As industries continue to evolve towards more advanced manufacturing solutions, the role of milling machines in achieving high-quality outputs will remain paramount.

Related Posts

-

Exploring the Future of Best Milling Machines in 2025 Industry Trends and Innovations

-

The Future of Precision Engineering: Revolutionizing Manufacturing with the Best Desktop CNC Mills

-

Ultimate Guide to Mastering Your First Desktop CNC Mill for Precision Engineering

-

How to Choose the Right Desktop CNC for Your DIY Projects

-

Unlocking the Future of Manufacturing at the 2025 China Import and Export Fair with Desktop CNC Machines

-

Ultimate Guide to Choosing the Perfect Home CNC Machine for Your Needs

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska