Best Desktop CNC Machines of 2026 What to Look For?

As the demand for desktop CNC machines rises, many factors come into play. Users range from hobbyists to professionals. Each person seeks to enhance their projects or products.

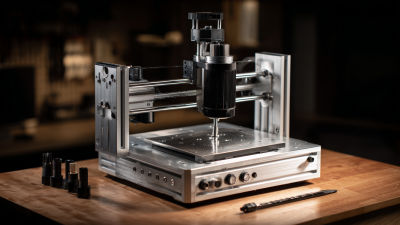

When choosing a desktop CNC machine, consider what you truly need. Size, speed, and precision are vital factors. A compact design may fit well in small workshops. However, power and capability should not be sacrificed. It is essential to assess the machine's durability as well.

Mistakes can happen. You might buy a machine that's too complex or not powerful enough. Research is crucial to avoid such pitfalls. Spending time learning about different features can save you money in the long run. Ultimately, finding the right desktop CNC machine is about balancing needs with capabilities.

What Makes a Desktop CNC Machine Ideal for Hobbyists and Professionals?

When exploring desktop CNC machines, understanding what makes them ideal for both hobbyists and professionals is crucial. The right machine can empower users to create intricate designs in wood, metal, or plastic. Users should look for precision and reliability. These machines need to provide consistent results. A sturdy frame enhances stability, reducing vibration. This stability is essential for achieving fine detail in projects.

Another important aspect is ease of use. A user-friendly interface saves time and decreases frustration. Some machines offer software that simplifies the design process. However, not all software is intuitive; some require a learning curve. It’s vital to investigate user reviews and tutorials. Additionally, consider the machine’s support and community resources. Engaging with others can significantly enhance the learning experience.

Power and speed also matter. A CNC machine's motor strength determines its ability to cut through harder materials. Yet, faster isn’t always better. Too much speed can lead to mistakes in detailed work. Users should balance speed with the quality of cuts. Reflecting on past projects can reveal where improvements can be made. Ultimately, aligning features with specific needs ensures a more satisfying experience.

Key Features to Consider When Buying Desktop CNC Machines in 2026

When considering a desktop CNC machine in 2026, key features make a significant impact. The machine's build quality is crucial. A sturdy frame ensures precision. Look for materials like aluminum or steel, which offer durability. Stability minimizes vibration, leading to better results. Pay attention to the machine's weight, as heavier designs tend to be more stable during operation.

Next, the cutting area matters. Assess the work envelope size based on your projects. A small machine may not accommodate larger materials. Additionally, the spindle power is essential. It affects cutting speed and material compatibility. A powerful spindle can handle various materials, from wood to metal.

Lastly, consider the software compatibility. User-friendly software enhances your experience. Some machines have proprietary software with a steep learning curve. Look for options that support popular CAD/CAM programs. This can save time and frustration. Ultimately, finding the right balance of features will enhance your CNC experience. However, remember that every choice has trade-offs.

Top Brands Dominating the Desktop CNC Market: A Statistical Overview

The desktop CNC market continues to evolve, showcasing innovative brands with remarkable statistical performance. In recent years, an emphasis on affordability has shaped buyers' preferences. Many users seek machines that balance precision with cost-effectiveness. The entrance of new players has introduced fresh competition. This has driven established brands to improve quality and features.

While several brands dominate the landscape, it is crucial to evaluate their unique offerings. Some may provide advanced software integration, while others focus on robust hardware design. However, not all promises are fulfilled. Customers often face challenges regarding technical support or machine maintenance. It’s essential to research user experiences to uncover potential pitfalls.

Market trends suggest that makers look for machines with versatile capabilities. Users desire products that can handle multiple materials effectively. Despite advancements, the learning curve can be steep for beginners. Many users report frustration with setup processes or software glitches. This highlights a need for more comprehensive tutorials and support systems in the industry.

Best Desktop CNC Machines of 2026 - Statistical Overview

| Feature | Metric | Value |

|---|---|---|

| Max Cutting Area | Width x Depth x Height | 600 x 600 x 100 mm |

| Spindle Power | Power Rating | 1.5 kW |

| Weight | Machine Weight | 50 kg |

| Precision | Movement Tolerance | 0.01 mm |

| Software Compatibility | Supported Formats | SVG, DXF, G-code |

| Max Speed | Travel Speed | 3000 mm/min |

| Operating System | Compatible OS | Windows, macOS |

| Price Range | Cost Analysis | $1200 - $3000 |

Analysis of Accuracy and Precision in Desktop CNC Machines Models

When choosing a desktop CNC machine, accuracy and precision are crucial. They define how closely a machine can replicate designs. A variance of even a millimeter can ruin a project. Many machines claim high accuracy, yet the real-world performance can differ significantly. Calibration becomes essential. Regular checks help maintain precision over time.

One key factor to consider is the spindle speed. Higher speeds can produce cleaner cuts. However, this may also lead to overheating. Finding a balance is important. Material choice influences accuracy as well. Some materials are more forgiving than others. Experimentation is often necessary. Users should document each process to refine their techniques.

Another point worth noting is the machine's stability. A sturdy frame minimizes vibrations, improving precision. Lightweight machines might be convenient but often sacrifice performance. Users may find themselves adjusting for imperfections in their work. An ideal setup involves a rectifying process to learn from mistakes. A thorough understanding of both strengths and weaknesses leads to better results.

Future Trends in Desktop CNC Technology and Their Impact on Users

Desktop CNC technology is evolving rapidly. Users can expect more intuitive interfaces and better software integration. These advancements will simplify design processes. Future machines will likely offer increased automation and connectivity. Imagine controlling your CNC via a smartphone app. This would enhance convenience and accessibility.

However, users must remain cautious. Not all improvements guarantee effectiveness. Some features may be complicated or untested. For instance, the concept of cloud-based machining raises questions about security and reliability. Users should also keep in mind the learning curve associated with new technologies. Not everyone adapts at the same pace.

Another trend is the push for sustainability. Machines may utilize eco-friendly materials, reflecting growing environmental awareness. However, the initial cost may deter potential buyers. It's essential for users to weigh the benefits against the investment. As CNC technology progresses, staying informed will be key to making wise choices.

Related Posts

-

Ultimate Guide to Mastering Your First Desktop CNC Mill for Precision Engineering

-

How to Choose the Right Desktop CNC for Your DIY Projects

-

Unlocking the Future of Manufacturing at the 2025 China Import and Export Fair with Desktop CNC Machines

-

Unmatched Excellence in Best CNC Metal from Leading Chinese Manufacturers

-

Discovering Quality Suppliers for the Best Mini CNC Machine in a Competitive Market

-

Exploring the Future of Best Milling Machines in 2025 Industry Trends and Innovations

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska