Navigating the 2025 Technology Trends with the Best Small CNC Machine for Metal

As we approach 2025, the manufacturing landscape is set to undergo significant transformations driven by emerging technologies. According to a report by McKinsey, about 70% of companies are already in the process of adopting Industry 4.0 technologies, which include automation, data exchange, and advanced manufacturing technologies. Among these innovations, the small CNC machine for metal stands out as a crucial tool for small to medium-sized enterprises (SMEs) seeking to enhance precision and efficiency in their operations. With the global CNC machine market projected to reach $100 billion by 2025, the rise of cost-effective and compact CNC solutions is empowering businesses to remain competitive while optimizing their production capabilities. This blog will explore the key technology trends shaping 2025, along with a practical checklist for selecting the best small CNC machine for metal, ensuring your business stays at the forefront of innovation.

Emerging Technologies Shaping Metal CNC Machining Trends in 2025

As we approach 2025, the landscape of metal CNC machining is being transformed by a number of emerging technologies. Innovations such as AI-driven machining, improved automation, and advanced materials are rising to the forefront, influencing how small CNC machines operate and what they can achieve. These technologies not only enhance efficiency but also significantly improve precision, which is essential for small-scale manufacturers looking to remain competitive in a fast-evolving market.

Tips for leveraging these trends include investing in a small CNC machine that incorporates AI capabilities. These machines can adapt in real-time to changing conditions and optimize machining processes on the fly. Additionally, consider adopting cloud-based software solutions that provide remote monitoring and management of your CNC operations. This can lead to reduced downtime and more efficient workflow.

Furthermore, don't overlook the importance of material selection. As new alloys and composites become available, staying informed about these options can help you achieve better performance and durability in your projects. Implementing these tips can position small manufacturers to take full advantage of the technological advancements shaping the future of metal CNC machining in 2025.

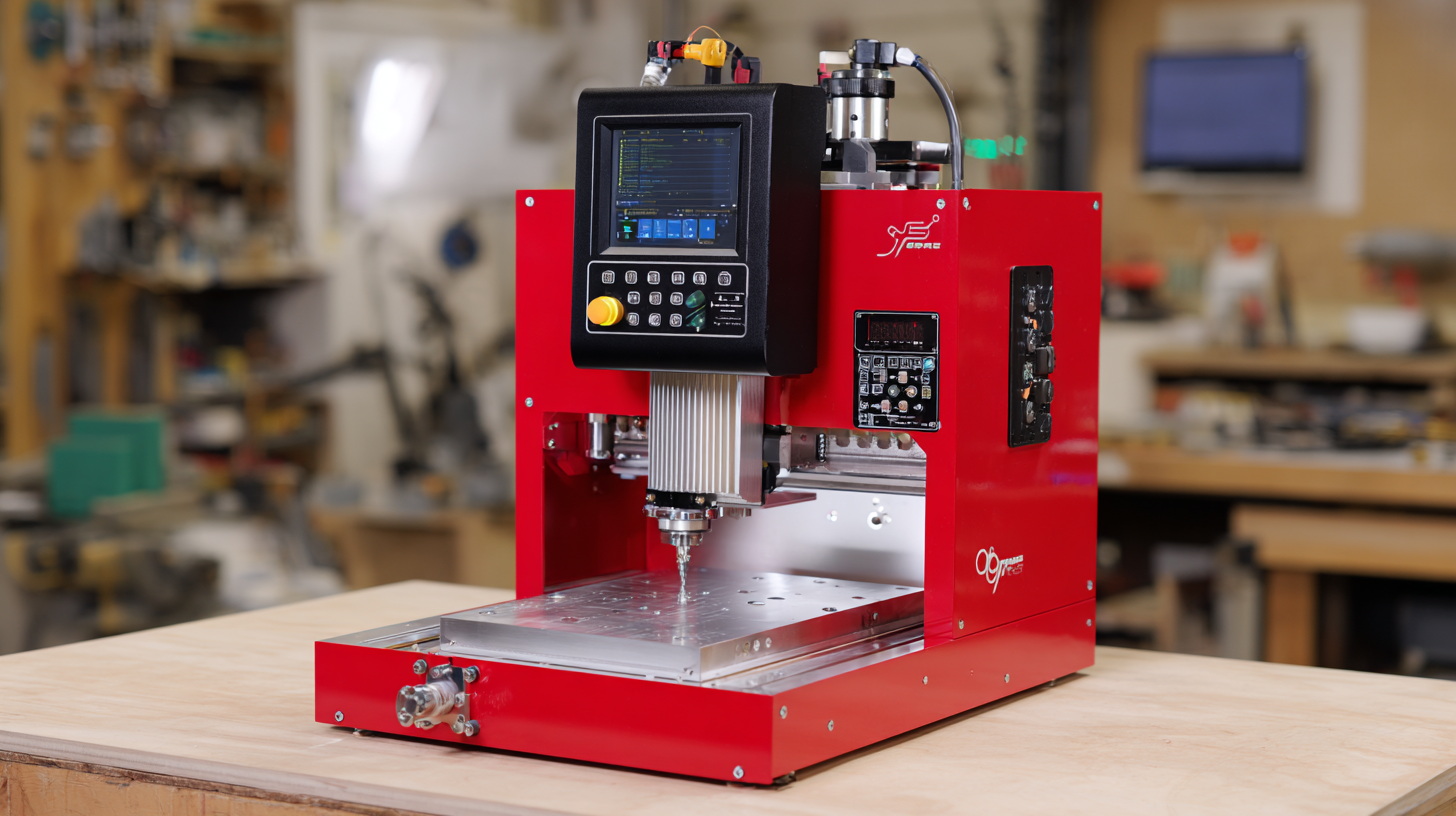

Key Advantages of Small CNC Machines in Precision Metal Fabrication

Small CNC machines are revolutionizing precision metal fabrication, offering significant advantages in today's manufacturing landscape. As the global CNC machine market is projected to grow from $101.22 billion in 2025 to $195.59 billion in 2032, the demand for high-quality, precise machining processes is on the rise. These small CNC machines provide enhanced capabilities for achieving intricate designs while maintaining tight tolerances, which is essential for industries such as aerospace, automotive, and medical devices.

One of the key benefits of using small CNC machines is their ability to streamline production processes. With modular design features, these machines enable manufacturers to increase both output and quality. By adapting to various production needs quickly, they allow for efficient workflows without compromising precision. Additionally, the rise of smart manufacturing under initiatives like "Made in China 2025" emphasizes the importance of technology integration, where small CNC machines can serve as integral components in creating added value and establishing higher technical barriers in precision manufacturing. As the industry continues to evolve, small CNC machines are poised to play a crucial role in meeting the growing demands for advanced metal fabrication solutions.

Industry Analysis: Market Growth and Technology Adoption Statistics for CNC Machines

The CNC machinery market is witnessing robust growth, primarily fueled by the increasing demand for high-precision components and automation across various industries. As businesses in sectors like automotive and aerospace strive for enhanced efficiency and productivity, CNC machines have become indispensable. Projections indicate that the global Computer Numerical Control (CNC) machine market could reach impressive valuations, with a significant CAGR anticipated through the coming years. This trend underlines the critical role that automation and smart manufacturing technologies will play in shaping the future.

In particular, the market for CNC vertical machining centers is expected to expand substantially, driven by the ongoing modernization of manufacturing processes. With technological advancements leading to the introduction of more sophisticated 3-axis and 5-axis machines, companies are investing heavily in CNC technology to stay competitive. Additionally, emerging markets, such as those in Saudi Arabia, are poised to benefit from initiatives like Vision 2030, which aims to bolster local manufacturing capabilities. As the landscape of CNC manufacturing evolves, the synergy between technology adoption and market growth presents significant opportunities for companies and investors alike.

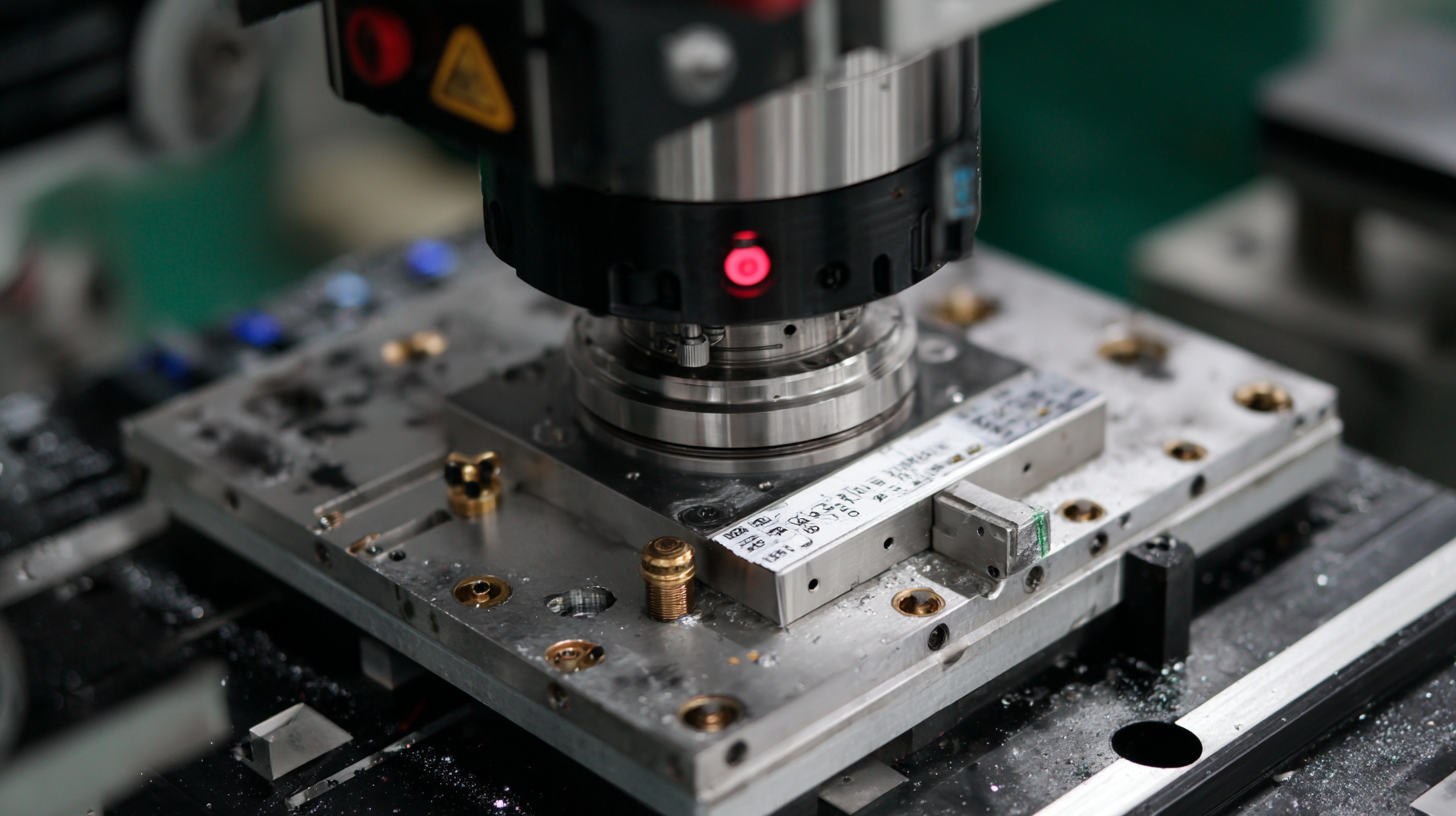

The Impact of Automation and AI on Small CNC Machine Efficiency and Output

The landscape of manufacturing is rapidly evolving, particularly with the implementation of automation and artificial intelligence (AI) in small CNC machines. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $117 billion by 2025, growing at a CAGR of 6.0%. This growth is driven by the increasingly sophisticated capabilities offered by automated systems and AI integration, which enhance the efficiency and output of small CNC machines.

Automation minimizes manual intervention, enabling manufacturers to streamline their workflows and reduce operational costs. For instance, small CNC machines equipped with AI can predict maintenance needs, which leads to less downtime and improved production rates. A study by the International Federation of Robotics indicates that companies adopting AI technology in their CNC operations have experienced productivity gains of 20-30%. As businesses look to optimize their operations, the combination of automation and AI positions small CNC machines as pivotal tools in achieving these objectives while maintaining high precision in metal fabrication.

Navigating the 2025 Technology Trends with the Best Small CNC Machine for Metal - The Impact of Automation and AI on Small CNC Machine Efficiency and Output

| Feature | Traditional CNC Machine | Small CNC Machine with Automation | AI-Enhanced Small CNC Machine |

|---|---|---|---|

| Setup Time | 60 minutes | 30 minutes | 15 minutes |

| Operating Efficiency | 70% | 85% | 95% |

| Error Rate | 2% | 1% | 0.5% |

| Maintenance Frequency | Monthly | Bi-Monthly | Quarterly |

| Production Rate (units/hour) | 10 | 15 | 20 |

| Cost of Operation (per hour) | $50 | $35 | $25 |

Sustainable Practices in CNC Machining: Trends for Eco-Friendly Metal Fabrication in 2025

As the landscape of CNC machining continues to evolve, sustainability is becoming an increasingly crucial focus in metal fabrication. In 2025, we can expect to see a surge in eco-friendly practices that not only enhance operational efficiency but also reduce environmental impact. One major trend is the adoption of renewable energy sources to power CNC machines. Manufacturers are exploring ways to integrate solar or wind energy into their operations, which not only lowers energy costs but also significantly decreases carbon footprints.

Additionally, the use of recyclable materials and innovative manufacturing practices is on the rise. The best small CNC machines for metal are now being designed with eco-friendliness in mind, featuring capabilities for handling recycled metals and minimizing waste generation. Techniques such as precision machining and adaptive tooling play a pivotal role in ensuring maximum material use. As more companies recognize the importance of sustainability, these practices will likely become standard, transforming the industry and paving the way for a greener future in metal fabrication.

Navigating the 2025 Technology Trends in Eco-Friendly CNC Machining

This chart illustrates the projected usage of various sustainable practices in CNC machining for 2025, highlighting trends that contribute to eco-friendly metal fabrication.

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska